How to Leverage Third-Party Logistics and Digitization to Optimize Your Consumer Electronics Supply Chain

It’s nearly impossible to imagine living in this century without electronics. They make up an essential part of our personal and professional lives and are inextricably entwined with them. They’re also a favorite in the world of business products as consumers are always on the lookout for the newest releases, next best deals and faster delivery options.

Everything from aerospace products to medical equipment to electrical household appliances make up the electrical and electronics industry. The industry is fast-moving and ever-evolving, with product life cycles resembling that of fashion retail. A product that is in demand one day can be replaced by newer, shinier product the next, making its supply chain complex and challenging.

Still, the growth of the Consumer Electronics (CE) industry is undeniable. Revenue in the Consumer Electronics market amounts to US$ 146,616m in 2021 and the market is expected to grow annually by 0.11% (CAGR 2021-2025).The industry churns out an overwhelming number of goods each year that look nothing like the products released the following year. The growth and evolution of electronic products depends not only on the way customers interact with and consume entertainment but also on how they manage their finances and organize their lives.

Growth of the Consumer Electronics

Revenue in the Consumer Electronics market

$146,616 million in 2021

Electronics supply chain turbulence caused by the pandemic

The industry has witnessed exceptional changes in the past decade or so. As digital media has gained prevalence, digital content creators and social media users have been playing a major role in driving demand for consumer electronic goods. Sustainability has grown to be more than just a passing trend and many regulatory pressures are now at play. Customers want cheaper devices without sacrificing quality, which means shorter life cycles, a bustling market and one too many choices.

In 2019, before the pandemic, the electronics industry was valued at 880 billion euros, which was around 20 percent of the global market. As with other industries, the CE industry also saw a slump in 2020, when the first Covid wave hit. Supply chain disruptions all over the world led to a shortage in the supply of electronic goods. A major reason for this was a global shortage of chips which was first felt in China and Taiwan—world’s leading chip-producing countries—where factories were shut down. The production recovered in the same year but was followed by new surges in demand, leading to a global shortage in 2021.

The recovery has been slow, but a period of growth is anticipated between 2020 and 2022.

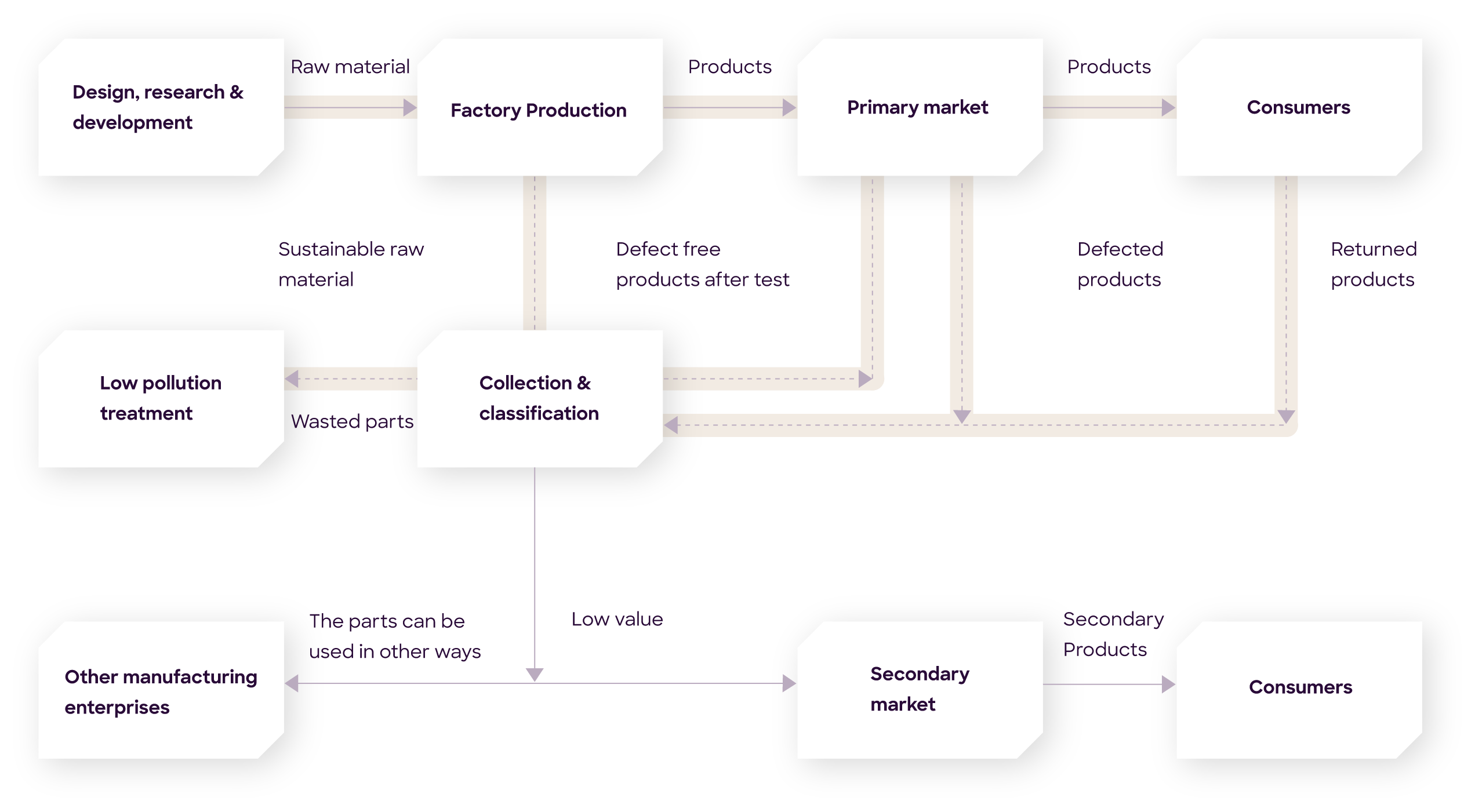

The Complex and Dynamic Supply Chain of Consumer Electronics

The consumer electronics industry is highly competitive and complex. The lifespan of consumer electronics is a short one and the industry also faces the heat when it comes to rapid changes in demand. Technological changes are so rapid that not being able to keep up with them is the number one reason many companies fail. These changes are also the reason for many mergers, acquisitions and divestiture activity.

Not only this, electronics companies have to sell to many vertical markets, each of which is unique. Other players in the consumer electronics supply chain include component suppliers, contract manufacturers, original design manufacturers, partners, distributors and value-added resellers, and finally, the end customers.

Most companies in consumer electronics have put a lot of money into information technology. Big investments lead to multiple systems and multiple point solutions that come with integration challenges. Efforts to expand technology often fail since most underlying structures are not strong or flexible enough to accommodate the complexity of multi-party structures. Warehouse and transport management systems can prove useful to such businesses.

Want to know how Locus can boost your profits?

Challenges faced by the electronics supply chain

Over the past few years, there has been an explosion in consumer demands, and manufacturers need to take a close look at their sourcing, distribution and inventory management strategies to stay ahead of competition. Here are some of the challenges faced by the electronics supply chain that need to be addressed effectively:

-

Sourcing from multiple places

-

Sourcing from many different suppliers from faraway places adds cost and complexity to the consumer electronics supply chain. Challenges with multiple suppliers show up in terms of quality control and efficacy. Lower order volumes leave little room for bargaining and contract negotiation is costly as well.

-

Sourcing from new and emerging markets

-

In an attempt to cut costs, several electronic companies have been reaching out for electronic logistics partners in emerging markets. The downside of this is that it makes the supply chain longer and more tedious. These markets are also often ill-equipped with and have insufficient infrastructure adding to supply chain complexities. Third-party logistics providers that have a firm hold in these markets can be of considerable help to businesses.

-

Customized products

-

Many companies adopt the made-to-order production strategy that customizes the products to the exact specifications of the customer. While this is a great way to attract customers, it is not always as cost effective as a made to stock model. Short product life cycles can also lead to inventories becoming obsolete.

-

High operating costs

-

One of the biggest logistical challenges for shippers is to reduce operating costs. Quick and costly air freight is the biggest contributor to this and the solution may lie in looking for cheaper alternatives. This is a tricky area because it requires planning beforehand which may not always be possible. Most customers want the delivery in no time which leads to electronics shippers opting for air freight.

-

Big carbon footprint

-

According to a United Nations report, global e-waste volumes grew by 21% between 2014 and 2019, with the US generating 6.92 million tons of e-waste, about 46 pounds per person. Only 15% of the material was recycled. If waste is generated at the same pace, e-waste will be doubled in just over ten years.

-

Packaging challenges

-

Electronic products are more prone to temperature and humidity changes, when compared with other product categories, and so they need to be packed accordingly. The size, weight and fragility of these products also presents transportation challenges.

-

Counterfeits

-

Consumer electronic firms need to be doubly sure of their suppliers and examine their goods carefully to ensure there are no counterfeit components in their goods. Serial number seals, and other e-pedigree techniques are viable solutions for this.

Third-party logistics providers: Enabling smooth functioning of the consumer electronics supply chain

The ever-evolving consumer electronics industry requires its supply chains to be flexible and agile so the newest changes can be adapted quickly. This means being able to deliver products to the consumer at the earliest, having a sound reverse logistics system, having multiple warehouses across the world and logistics providers with access to international shipping routes.

Third-party logistics providers work closely with electronics shippers and freight carriers to help them get a clearer picture of their goods in transit. They simplify transport management by keeping track of all necessary information about supply chain operations in one place.

All-Mile logistics makes up an essential part of the supply chain, and delivering the products without a scratch and on time is especially important for the electronics sector. All-Mile delivery can make a big difference in the success of a business, and 3PL companies enable efficient all-mile deliveries.

One of the biggest challenges for electronics shippers is greater supply chain visibility and third-party logistics providers can help with that. Greater visibility brings greater security with it and is crucial in keeping customer information and order status up to date. Along with improved forecasting, visibility also works as a great cost-saving strategy for businesses.

Locus in the consumer electronics supply chain: Optimizing logistics with AI

The consumer electronics industry is currently witnessing an unprecedented change. The pandemic, the development in social media in recent years and digital content have all contributed to a surge in demand for electronic products.

This explosive growth is also coupled with competition and the only way to stay ahead of the curve is by partnering with a third-party logistics provider. Locus solutions can not only help leverage the opportunities provided by this demand, it can also help businesses succeed by tightening their forecasting, sourcing, distribution and inventory management strategies. Here are some of the ways in which Locus can aid consumer electronics businesses:

-

Create advanced dispatch plans

-

Traditional methods don’t make the cut when it comes to keeping up with the ever-growing electronics’ demand. DispatchIQ, the routing software can help with the intelligent clubbing of orders so that daily dispatches can be planned with ease. Locus’ geocoder simplifies complex addresses in no time and puts them on a map, speeding up all-mile performance.

-

Track orders in real-time

-

An advanced fleet tracking system and insights are provided by TrackIQ, so both the customer and the company know the Expected Time of Delivery (ETA). Locus On the Road App (LOTR) also helps delivery executives with route schedules and navigation.

-

Make smarter supply chain decisions

-

While daily dispatches solve many supply chain problems on a regular basis, Locus’ solutions for the consumer electronics industry can also be sought for long-term planning. FieldIQ, the territory mapping software, can be used to improve resource utilization and increase the operational efficiency of the electronics supply chain. It can help to create Optimized Permanent Journey Plans (PJP) and Permanent Dispatch Plans (PDP), both of which can be customized to suit the businesses’ particular needs.

-

Plan for the future

-

An intelligent network optimization and design engine that uses advanced deep data principles to carry out data sanitization is Locus’ NodeIQ. It also provides intuitive data sets that are fit for analysis and securing revenue-generating insights. Its most popular feature is creating a ‘digital twin’ of the supply chain with a geospatial visual simulation that can run all possible alternative scenarios and help future-proof your supply chain.

A fluctuating market needs resilient supply chains to depend on. The consumer electronics industry can benefit greatly by partnering with third-party logistics providers and technology partners who can help simplify their logistics and bring greater visibility and security to businesses.

Resources

Case Study

How to increase operational efficiencies in E-commerce

With E-commerce becoming more complex, thanks to increasing customer demands, it is imperative to increase operational efficiencies across all-miles.

Read moreBlog

How Delivery Logistics Software Benefits Brands Involved in Alcohol/Beverage E-commerce?

Read moreRunning an e-commerce business is all about offering convenience and keeping the promise of speedy deliveries. Now optimize your e-commerce supply chain with AI-powered logistics solutions by Locus.

Get in touch with our experts for a quick tour of our solutions.