Decoded: The A to Z of healthcare logistics

Of all the industries in the global economy, healthcare is truly unique as it is directly responsible for the lives of billions across the world. Population growth, coupled with advancements in medical technology and improved access to healthcare, has meant the continual flourishing of the industry.

According to Deloitte, healthcare spending globally is expected to rise and will continue to be a vital pillar of economic growth and development.

As with many industries, the effective functioning of the healthcare industry is underpinned by the efficiency of its underlying supply chain. However, the coronavirus pandemic has forced the industry to reconsider the principles and priorities their supply chains run on.

Understanding the myriad factors behind this disruption requires knowledge of how the supply chain works. An uphill task, given that its complexity is arguably analogous to the complexity of administering healthcare itself!

Here, we will break down the various components of healthcare supply chains and how they work together, their various stakeholders, key trends shaping supply chains of today, and the importance of bringing resilience to supply chains.

Compound annual growth rate (CAGR) of healthcare spending

Globally, healthcare spending is expected to be at

10.3% in 2023

The various arms of healthcare logistics

To ensure that patients get the healthcare products they need, supply chains grew to become incredibly efficient. And incredibly complex.

Healthcare supply chains are notorious for spanning across several touchpoints and geographies. A McKinsey report noted that such supply chains could start in Asia and circumnavigate the globe twice!

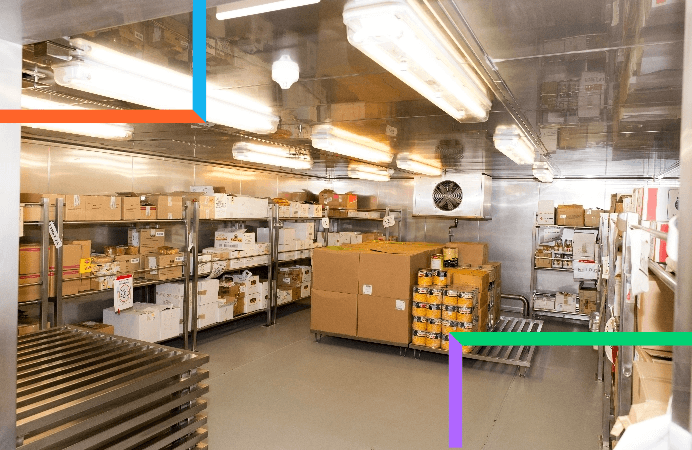

Despite this immense complexity, healthcare supply chains can broadly be categorized under three types: the first mile, the middle mile, and the all-mile. The principal players of the first mile are pharmaceutical companies and medical equipment manufacturers.

Once an order is placed with these drug makers and product manufacturers, they are shipped off to distribution centers. From here, these products are then shipped to the hospitals, clinics, other healthcare centers, and pharmacies that ordered them. The transportation of products from the manufacturer to distribution centers and the healthcare centers constitutes the middle mile.

The patients are central figures of the all-mile in the supply chain, as it involves the delivery of drugs and other healthcare products to patients. Online pharmacy and healthcare companies have been making their mark in this space with rapidity. A big reason for this is the growing popularity of online healthcare services and telemedicine in a post-pandemic world.

2X Investment in digital health by venture capitalists in 2020 in comparison to 2017

Source: Rock Health’s H1 2021 digital health funding report

As a result, providing healthcare is no more confined to traditional centers such as hospitals and clinics. Healthcare can now be provided at a patient’s home in many instances, making the all-mile delivery of healthcare products crucial.

Healthcare logistics: From past to the present

Up until the ’80s, healthcare supply chains were largely decentralized, and its operations were manually run. Each hospital or healthcare center would periodically compute its supply needs and meet them by individually reaching out to vendors. In essence, every healthcare center was an island that was operating and maintaining its supply chain.

However, this meant that hospitals had little leverage against suppliers, leading to increased costs, which also reflected as high healthcare costs for patients. The manual process of taking inventory also had greater scope for making errors, often leading to oversupply and eventual wastage. The reverse is also true, where clinicians would often not have their desired products at hand.

Since then, supply chains have evolved to become more centralized. Concepts such as integrated delivery systems (IDSs) have helped hospitals’ supply chain managers gain greater inventory visibility. IDSs are essentially a conglomerate of healthcare companies owned by a single parent company. They enable a flow of data and necessary resources, and also allow healthcare companies to enlist the help of group purchasing organizations (GPOs). These are third-party organizations that often pool the procurement needs of multiple hospitals to gather collective bargaining power from suppliers. Thus, GPOs help reduce the expenditure on supplies and make healthcare more accessible.

The past decade has seen more significant efforts towards the digitization of information, advancements in logistics technology and innovation, and the increased adoption of data analytics. The end goal is improved supply chain visibility, better inventory tracking, and reduced wastage of supplies.

$2.08 billion

Estimated value of the supply chain management market in 2021

9.3%

CAGR of supply chain management market in 2021-2028

The pandemic has accelerated the digitization of the healthcare supply chain and telemedicine and digital healthcare. All these trends have led to the maturation of the all-mile in the healthcare supply chain.

38X

Increase in telehealth usage in 2021 from pre-COVID-19 baseline

$14.7 billion

Funding received by the US digital health sector in H1 2021, up from $1.1 billion in 2011

As a result, patients can now receive healthcare services and medicines at their homes, often on the same day, thanks to the parallel advancements in supply chain logistics.

Want To Know How Locus Can Boost Your Profits?

Challenges shaping healthcare supply chain optimization

Supply-demand mismatches

While the motivations behind the various stakeholders in the supply chain might differ, they all operate on a fundamental principle: to facilitate the best possible healthcare, both patients and clinicians must have access to the relevant healthcare products in a timely manner.

This is a task easier said than done. Given the diverse spectrum of ailments and equipment needed to treat them, hospitals on average stock up an average of 6,000 to 8,000 stock keeping units (SKUs). They are estimated to have close to 35,000 products on their formulary, which is the list of drugs and medicines that they can count on to buy at any time.

Estimated percentage of total hospital budget earmarked for supplies in 2019.

Product choice of clinicians is also one of the major factors affecting supplies at hospitals. If there is a lack of communication over stocking these products, hoarding becomes commonplace. On the other hand, catering to the diverse choices of all clinicians could mean overstocking of supplies and eventual wastage.

Ex: A US-based hospital managed to save $30,000 a year by reducing the number of sanitizers it stocked in its healthcare system from 30 types to three.

The vast increase in uncertainty over supply chain

The COVID-19 pandemic has arguably been one of the strongest change drivers in the healthcare logistics space. It has exposed the weak links in having efficient supply chains spread over many countries.

38%

Estimated percentage of one year’s earnings that MedTech companies could lose over a 10-year period from shocks.

24%

Estimated percentage of one year’s earnings before interest, taxes depreciation and amortization that pharmaceutical companies could lose over a 10-year period from shocks.

$40 billion

Loss caused by forty weather disasters in 2019

2X

Increase in the number of ransomware variations from 2018-2019

The spectrum of risk has also evolved, ranging from cyberattacks to disruptions caused by tariff wars and political instability, to force majure events such as earthquakes, tsunamis, and even pandemics. The interconnectedness of supply chains means that such disruptions can have ripple effects throughout the healthcare industry. This has made resilience one of the top priorities for supply chains. In the past, supply chain resilience would come at the cost of efficiency. However, developments in supply chain technology and management are making it possible for both qualities to go hand-in-hand.

Manual operations and lack of data visibility

Right from sourcing to taking inventory and resolving payments, all important functions across the supply chain were carried out manually for most of the 20th century. Such methods placed a cap on the efficiency of these functions, especially if a supply chain sought to grow in scale.

Manual supply chain tasks have a negative impact on patient care, according to 45% of respondents in a survey of hospital supply chains

Supply chain tasks take too much time away from patient care, according to 45% of the respondents surveyed.

As is the case with manual operations, there is also a tendency for data to accumulate in siloes, which reduces the visibility of data and the overall health of the supply chain. This also presents fewer opportunities for holistically analyzing the data to uncover areas of improvement.

Technologies affecting supply chain visibility

Aside from the business imperatives, well-functioning healthcare supply chains are foundational to improving the access and quality of healthcare. In a post-pandemic world, this means maximizing supply chain resilience alongside efficiency.

Total number of respondents who agree that supply chain management is crucial to solving key challenges

As a result, supply chain risk management is as important as optimization in an increasingly uncertain world. Enhancing these functions has been largely been due to technology adoption and banking on trends such as:

Internet of Things (IoT)

Devices that can communicate with each other over the internet have been fundamental to promoting supply chain visibility. Thanks to IoT, any healthcare consignments can be tracked from the first mile till the end-consumer at the all-mile.

Locus’ TrackIQ, a leading fleet tracking software, provides complete visibility on the ground with a LiveView Dashboard, which can help prepare for any unforeseen eventuality. It also helps delivery executives complete more tasks by showing the most optimal route.

Finally, for healthcare companies working in the all-mile space, customer experience is crucial to differentiating themselves in a highly competitive arena. TrackIQ’s white-labeled via.sh links can help end-customers track the status of the healthcare products they ordered and even collect their feedback.

Automation

Automation allows for the quick completion of repetitive tasks with greater efficiency. This allows for supply chain executives in the healthcare space to focus their energies on building supply chain resilience and scaling their operations.

It is now possible for the supply chain departments of hospitals to automate sourcing, inventory purchasing and management with the help of supply chain, and inventory management platforms. With the power of Artificial Intelligence and Machine Learning (AI/ML), the capabilities of such platforms are only expected to get more advanced in the future.

For those healthcare and digital companies in the all-mile delivery space, Locus’ Orchestration is a platform that optimizes the whole shipping process with the help of automation. For example, it allows for the automated pushing of orders through a custom rule engine and provides seamless carrier management through pre-negotiated rates, minimum guarantees, and automated payments and reconciliation.

Data Analytics

AI/ML has been largely responsible for the data revolution of the past decade. When it comes to supply chain management and logistics, it is reflected in the quality of insights that help companies improve their performance on essential metrics and hold service level agreements with incredible precision.

Locus DispatchIQ, an advanced routing software, helps achieve these with the help of its powerful analytics engine. It enables cost-based route optimization, which plans out the routes of entire fleets by considering real-time variables and constraints such as traffic, fuel usage, the nearness of locations to each other, among others; optimization of a fleet mix, which ensures that all the vehicles and executives are optimally engaged and also cater to customer preferences; smart rider allocation, which also considers the skill sets of the various delivery executives and real-life factors like lunch breaks, sick days for drivers, and time slots.

Similarly, Locus TrackIQ can bring out patterns of various fleets by analyzing metrics such as mileage performance, driver history idling, and stoppage times thanks to its data analytics capabilities.

Predictive Analytics

Healthcare supply chains are finding it essential to be ready for the inevitable shocks coming from an increasingly uncertain world. According to a McKinsey study, conducting detailed risk diligence, understanding the magnitude and likelihood of potential risks, and incorporating supply chain best practices are some of the must-dos for building resilient supply chains.

However, many structural changes to build supply chain resilience require a lot of capital investment, making it important to ensure that these investments will yield desired results.

Backed by advanced predictive analytics capabilities, Locus NodeIQ is a network design software that helps decision-makers create a ‘digital-twin’ of the existing network design of their supply chains. With the help of this twin, they can run ‘what-if’ scenarios to factor in likely risks and even see if any changes to their supply chains make them more efficient and resilient.

Supply chains worldwide continue to face tremendous challenges even as we inch close to two years since COVID-19. According to a New York Times article, supply chain bottlenecks and delays will likely continue through 2022. In such a scenario, resiliency and optimization need to go hand-in-hand for any hope of sustainable growth in the future.

Since 2016, Locus has been leveraging the latest technology to redefine the face of logistics.

To know how you can optimize your supply chains and make them more ready for today’s world, click here for a demo with team Locus today!

Resources

Infographics

Top Five Challenges and Lessons for Businesses in Enabling Same-Day Prescription Deliveries

With an increased demand for prescription deliveries, find out the top five challenges and lessons for businesses in enabling same-day prescription delivery.

Read moreIn today's digital age, healthcare business need to offer their services from the convenience of people's homes wherever possible. Optimize your healthcare supply chain with AI-powered logistics solutions by Locus.

Get in touch with our experts for a quick tour of our solutions.