What is Direct to Store Delivery all about?

Over the past few years, competition in the retail industry has intensified. As customer demands for speed and convenience are increasing by the day, more businesses are embracing omnichannel selling methods.

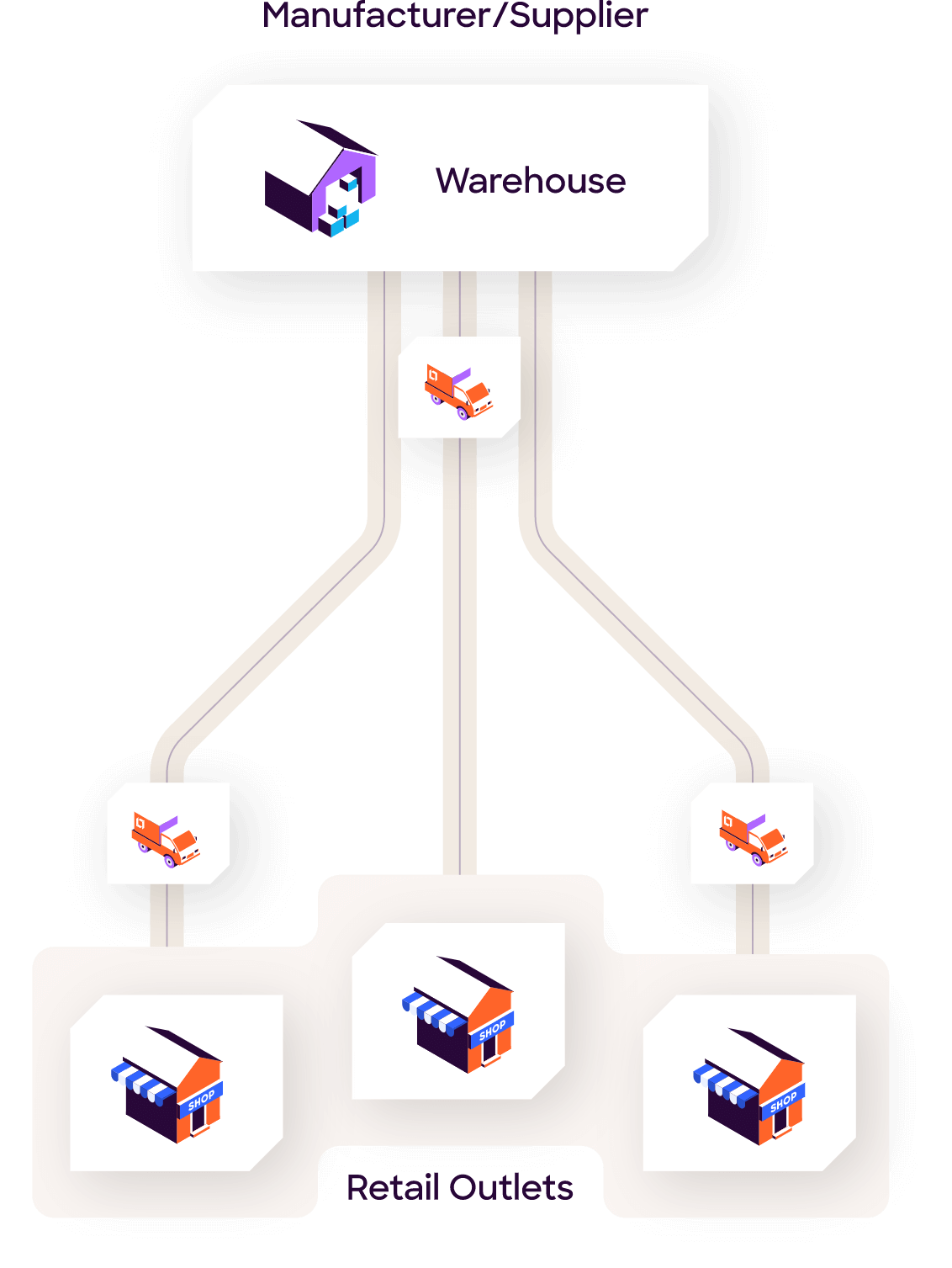

Direct to Store Delivery or Direct Store Delivery (DSD) is a retail distribution model, where a supplier or manufacturer delivers merchandise directly to retail stores for selling, instead of sending them to warehouses or distribution centers.

Direct Store Delivery is gaining popularity among businesses involved in the retail of pharmacy drugs, fresh foods, edible consumer goods such as baked foods, snacks, soft drinks and beverages, organic farm produce, and locally produced alcohol, etc.

Going direct to retail outlets or in some cases even the end customer allows businesses to save time and cost involved in wholesale distribution or storage in secondary warehouses.

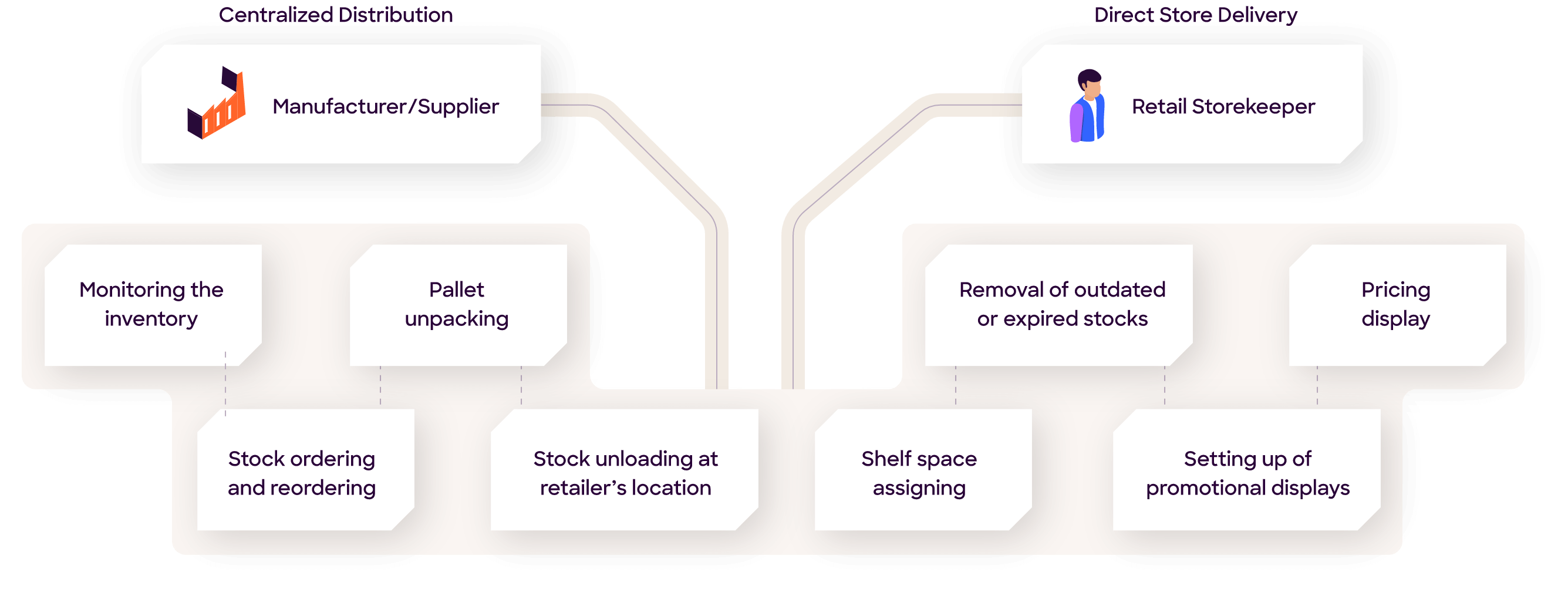

How is Direct Store Delivery different from centralized distribution?

In a centralized distribution model, the supplier or manufacturer delivers finished goods to a primary warehouse. From this primary location, it is further transported to various distribution centers within cities or directly to retail outlets as and when the requirement arrives. This is typically a periodic process, wherein a store manager calls the warehouse to place an order. The ordered quantity is then shipped from the warehouse or distribution center to the retailer to replenish stocks. In this model, the retailer is completely responsible for inventory management. On the other hand, in the case of a direct to store delivery, the inventory management, and shipment load moves to the manufacturer or supplier.

Want to know how Locus can boost your profits?

How is DSD delivery different from distributor-led delivery?

Typically, manufacturers rely on intermediaries called distributors to make sure that their products reach the retail stores that are frequented by consumers. Leading distributors are known to have an extensive network of warehouses and distribution centers, and have a large fleet at their disposal. But distributors are known to provide functions beyond just deliveries and logistics. They often have strong relationships with retail groups, given that they tend to focus on a single market. Many of them actively sell and market the products of the manufacturers that they work with. The upside? A chance for manufacturers to focus on what they know best, and increased sales to boot. But the downside of it is that distributors charge steep commissions, which may not be sustainable for all manufacturers to commit to. This is especially relevant for manufacturers of products with lower profit margins, or those looking to scale up in the near future

Business benefits of implementing a Direct Store Delivery model

The DSD retail model is widely used as a primary distribution method in retail, especially the distribution of fast-moving consumer goods and perishable items. Let’s look at some of the advantages of this distribution model for retailers and consumer goods manufacturers.

-

Enables quick time to market

-

As the DSD distribution model eliminates middlemen touchpoints such as wholesale dealers, it significantly reduces the overall time to market, allowing suppliers/manufacturers to deliver merchandise faster. It also helps retail storekeepers to replenish stocks quicker and improve customer satisfaction by keeping inventory stocked up sufficiently at all times.

-

Allows effective handling of perishable/

fragile goods -

Perishable consumer goods such as fresh fruits, vegetables, flowers, poultry items, and bakery products are time-sensitive and need careful handling, sometimes in special containers such as wooden trays or even refrigerated trucks. Fragile goods such as potato chips, biscuits, wafers, or snacks also need special care during packaging and shipment. With DSD logistics, merchandise is packaged and shipped at the manufacturer’s location and transported directly to the end retail market, thereby minimizing the risk of damage to these fragile consumer goods and improving the efficiency of handling the goods.

-

Boosts seasonal selling

-

Some retail businesses earn additional revenue by selling seasonal goods such as festival merchandise, summer fruits, winter vegetables, Valentine’s special flowers, Halloween candies, or even non-consumables such as umbrellas, raincoats, festive decoration items, Christmas goodies, and so on. Direct Store Deliveries are immensely profitable during these peak seasons when the demand for such special goods is high and there is a limited time for manufacturers to make them available in the market.

-

Minimizes supply chain costs

-

By implementing the DSD retail model, businesses can reduce storage and labor costs by completely skipping secondary distribution and warehousing. As businesses can directly deliver goods to retail markets, there is no added cost such as the fee paid to wholesale distributors to sort, package, and ship goods, or the rental amount payable to centralized distribution centers for storage of merchandise.

-

Builds stronger brand-retailer relationship

-

The Direct Store Delivery method connects a brand directly to the retailer, building a better relationship with the end market players. As the brand sells goods directly to retailers, it gives them regular market insights — what are the consumers buying more, the recent market trends and demands, and which products are not doing well in the market. This information allows brands to strategize better and sell effectively.

-

Streamlines shelf-space management

-

As retail inventory management is carried out by the supplier or manufacturer, it reduces the retailer’s burden of keeping a check on inventory levels and replenishing stocks periodically. Dealing directly with suppliers allows retailers to fulfill market demands effectively, streamlining shelf-space management. It also allows brands to push items with higher consumer interest and thereby increase their sales.

Implementing a Direct Store Delivery model in your supply chain

Whether you’re revisiting your supply chain strategy to fulfill customers faster, or meet the seasonal dynamic demands of the retail market, or looking to implement a more cost-effective distribution model, Direct Store Delivery is the best way forward. While implementing DSD might seem overwhelming, you can ensure a smooth transition by following these simple steps.

Plan your DSD strategy

Do you want to implement direct store deliveries as an additional or seasonal distribution model along with your existing retail distribution model, or do you wish to move to a DSD model completely? Begin your implementation by figuring out the tenure of DSD in your business. It will allow you to narrow down your secondary distribution effectively.

Build a market presence and understanding with retailers

You might already be dealing indirectly with the end market through your distributors or wholesale dealers, but when it comes to Direct Store Deliveries, you have to deal with the retailers directly. You have to understand market dynamics from the ground up and build a relationship to enable smooth direct store deliveries in the long run.

Plan your delivery routes

The most crucial step in going direct to the store would be to plan your delivery routes to hundreds of retail stores spread across multiple locations effectively. Manual route planning will not cut it as it is both tedious and error-prone. An efficient route planning software can help in streamlining the whole process.

Develop a feasible sales beat plan

Depending on the population density in a locality, or the demand for a certain category of products, stock replenishment timelines may vary from one retail store to another. As a direct-to-store distributor, you must plan your sales beat flow effectively in order to remain cost-effective and efficient. Sales beat is the permanent journey planning of salesmen for a defined period to decide which outlets to visit, who should visit a store, the right time to visit, and how to visit in order to replenish retail stocks.

Deploy and manage the delivery fleet

In a conventional distribution model, brands typically send finished goods to a secondary dealer, and the dealer then takes over the distribution to retail stores and customer markets. In the DSD model, this responsibility lies with the brand itself. Therefore, careful planning and management of the delivery fleet is vital — how many owned vehicles vs. how many rented vehicles should be deployed in the delivery, and how to manage these fleet vehicles once they hit the roads?

Do you want to implement direct store deliveries as an additional or seasonal distribution model along with your existing retail distribution model, or do you wish to move to a DSD model completely? Begin your implementation by figuring out the tenure of DSD in your business. It will allow you to narrow down your secondary distribution effectively.

You might already be dealing indirectly with the end market through your distributors or wholesale dealers, but when it comes to Direct Store Deliveries, you have to deal with the retailers directly. You have to understand market dynamics from the ground up and build a relationship to enable smooth direct store deliveries in the long run.

The most crucial step in going direct to the store would be to plan your delivery routes to hundreds of retail stores spread across multiple locations effectively. Manual route planning will not cut it as it is both tedious and error-prone. An efficient route planning software can help in streamlining the whole process.

Depending on the population density in a locality, or the demand for a certain category of products, stock replenishment timelines may vary from one retail store to another. As a direct-to-store distributor, you must plan your sales beat flow effectively in order to remain cost-effective and efficient. Sales beat is the permanent journey planning of salesmen for a defined period to decide which outlets to visit, who should visit a store, the right time to visit, and how to visit in order to replenish retail stocks.

In a conventional distribution model, brands typically send finished goods to a secondary dealer, and the dealer then takes over the distribution to retail stores and customer markets. In the DSD model, this responsibility lies with the brand itself. Therefore, careful planning and management of the delivery fleet is vital — how many owned vehicles vs. how many rented vehicles should be deployed in the delivery, and how to manage these fleet vehicles once they hit the roads?

Learn how Locus can help your business save costs and increase revenue

Logistical challenges in Direct Store Deliveries

When a brand adopts the DSD route, it has to look after end-to-end shipping and transportation of the merchandise. Although the DSD model is faster and more transparent, it leads to an increase in transportation costs, thereby increasing the overall supply chain operating costs for the business.

Proper packaging and shipping of goods play a crucial role in ensuring that the consumer goods reach the market in the most ideal condition. However, brands that usually send merchandise to secondary distributors may not have the right expertise on packaging and shipping of the goods, which may lead to inefficiencies through the supply chain journey. This is especially problematic in the case of fresh foods such as fruits, meat, vegetables, or poultry foods.

The notion that business is becoming more complicated is acknowledged worldwide. Brands that are new to the Direct Store Delivery format may find it difficult to accommodate real-time order requests or dynamic changes in delivery schedules. As the business landscape has turned complex and more competitive, businesses are seeking ways to boost their operational efficiency. The inflexible DSD supply chains make it difficult to find untapped revenue potential. Hence, it is necessary to use tools that add transparency, responsiveness, convenience, visibility, and flexibility.

Logistics managers in the Direct Store Delivery business often find it difficult to manage and monitor delivery fleets running in multiple directions for retail distribution. They are tied up with the responsibility of ensuring the goods reach retail locations within the stipulated timelines, there are no delays or latency in the journey, and that the delivery staff is performing their duties efficiently. Manually coordinating with the on-ground staff and keeping a track of delivery operations might be overwhelming and inaccurate, and there is a clear need for a supply chain visibility tool that can solve this problem.

The biggest challenge is efficiently connecting the dots between the DSD brand, distribution staff, and the retailer. Another challenge commonly faced by brands is the lack of coordination on delivery status, product inventory, pricing changes, etc. This is crucial as it impacts profit margins heavily.

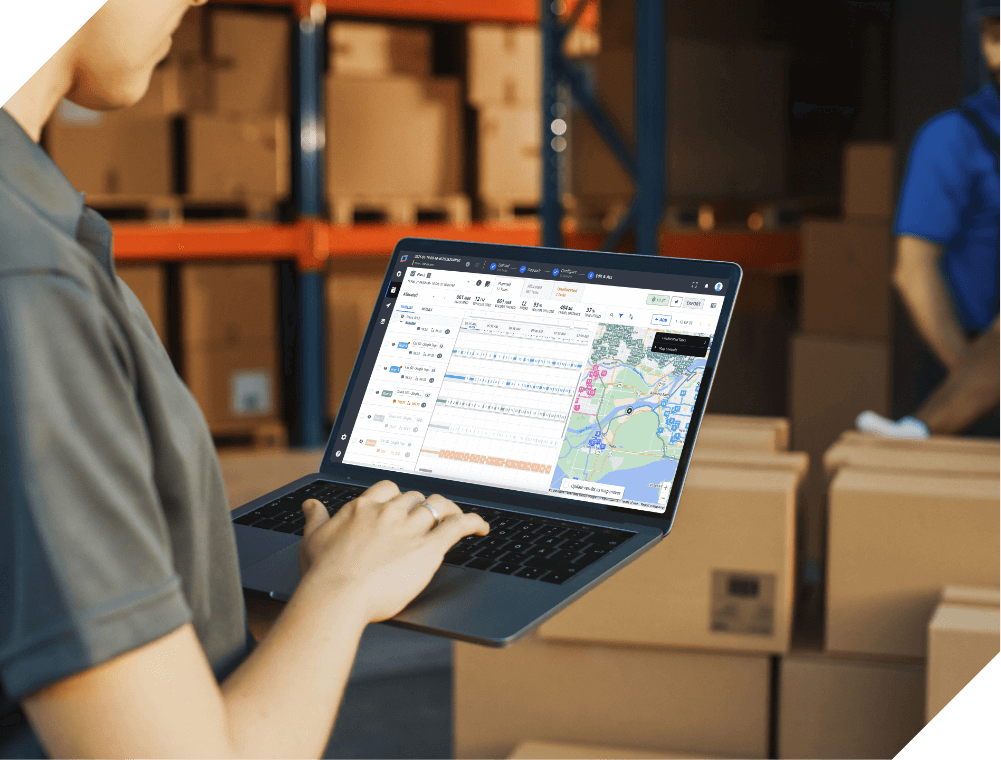

Locus in the Direct Store Delivery supply chain

Locus offers state-of-the-art logistics technology solutions to enterprises involved in Direct Store Deliveries, optimizing the DSD supply chain with automated route planning, real-time visibility, fleet management and more. Locus offers logistics tech to enterprises in a Software-as-a-service (SaaS) model that is fast and easy to implement, and does not require a huge initial investment. SaaS solutions run on a pay-as-you-go model that allows scaling up and down based on business requirements and market trends. Moreover, Locus’ AI-enabled tech is hosted and managed on the cloud, which makes it seamless and secure.

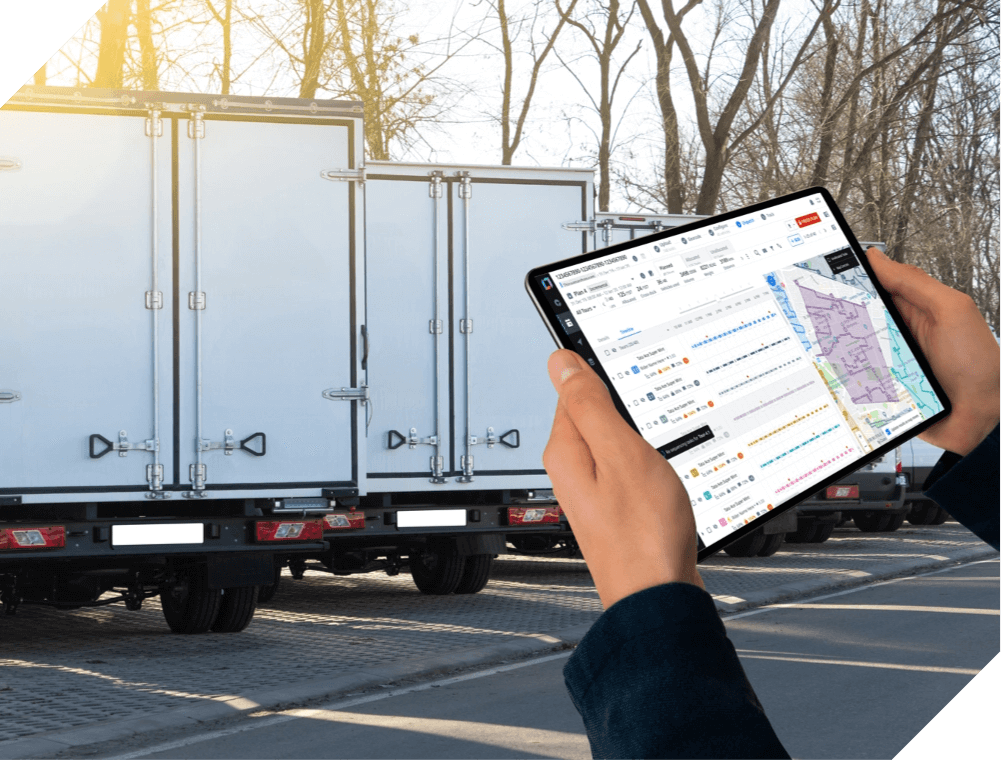

Delivery route planning and optimization

Locus’ AI-enabled logistics planning software, DispatchIQ allows brands to plan delivery routes automatically, optimize delivery schedules and handle on-demand orders along with scheduled orders with rerouting on the go.

It minimizes human dependency involved in the conventional pen and paper logistics planning, and helps in planning the shortest and most optimal routes for multiple delivery locations. Taking shorter routes improves retail serviceability, speeds up deliveries and reduces fuel costs for the business. Know more about Locus’ route planning software

Smart retail sales beat planning

As the entire responsibility of monitoring retail inventory and replenishing stocks lies with the brand in Direct Store Deliveries, it is essential to have a systematic sales beat plan in place. Locus’ beat planning software drives sales growth and effective utilization of sales executives, in turn bringing efficiency to dispatch operations. Automated beat planning maximizes the number of touchpoints in a beat, increases face-time with retailers vs time spent travelling, and thus improves sales effectiveness and efficiency.

It also takes into account factors like geographical proximity, familiarity of a salesman with a retailer, salesman’s geographical knowledge, SKU familiarity, store visit frequency to come up with a daily, weekly, or fortnightly replenishment plan.

Intelligent shipment sorting

With the help of Locus’ AI-backed shipment sorting and rider allocation software, brands can reduce human dependency in sorting day-to-day delivery packages and improve distribution efficiencies in Direct Store Deliveries. This allows brands to reduce the significant amount of time spent on manual sorting processes and improve accuracy in the process. Routes can be printed on the shipping label to eliminate the manual dependence, thereby saving additional time by simplifying the look-and-pick method that is traditionally followed in shipment sorting.

Optimal fleet mix and vehicle allotment

When going direct to stores, brands need to deploy their own fleet to carry out delivery operations. While they might own some vehicles, they may have to rent some. Locus’ FleetMix is a strategic tool that considers historical data and real-time demand trends to propose the comprehensive fleet mix plan to meet business requirements.

Locus’ advanced analytics helps businesses analyze the right number of vehicles, the right class/ type of vehicle to fulfill delivery demands, and reduce under-utilized space by planning deliveries for every task.

Real-time visibility and tracking

Logistics managers in a Direct Store Delivery model must proactively monitor and track on-ground operations to ensure that every shipment reaches on time, without any significant damages or delays in the schedule.

Locus TrackIQ is an AI-backed fleet optimization software that enables brands to track fleet movement in real-time and trace workforce performance remotely with the help of intuitive dashboards. TrackIQ also provides predictive alerts in case of any deviation from the planned activities, and offers granular insights to plan future deliveries better.

Is a Direct-to-Store Delivery model right for you?

Resources

E-book

How a Dispatch Management Platform Optimizes Your All-Mile

There’s a lot that goes into making a delivery successful. Manual and repetitive tasks must be automated, warehouse and delivery operations streamlined, human errors reduced, resources utilized efficiently, and service level agreements adhered to.

Read moreWhether you’re setting out for the Direct Store Delivery journey for the first time or willing to optimize your existing DSD supply chain, Locus can help you improve logistics efficiency and stand out from competitors.

Get in touch with our experts for a quick tour of our solutions.