Route Smarter, Deliver Fresher for Publix — Powered by Locus

AI-driven routing, temperature visibility and real-time control-tower alerts that keep 1,410 stores stocked and curbside orders on time while a fleet of owned tractors and 3-party carriers criss-cross eight Southeast states.

Locus Market Recognition From Gartner For 5 Consecutive Years

See Locus in Action — For Publix Super Markets

Chosen by global brands in 30+ countries over the last decade

Locus Keeps Publix’s Regional Supply Chain in Top Shape

Publix is pouring $2.6 billion into new stores, tech and warehouses, including a frozen-foods DC in Jacksonville, to feed explosive curbside and delivery demand.

Locus knits routing, fleet, temperature and labour data into one optimisation engine—so Publix hits every promise without inflating cost-to-serve.

Fleet Utilisation

600 tractors & 3,000 trailers need tighter routing as the network grows.

Last-Mile Efficiency

Dense metro store drops demand multi-stop precision to keep shelves full.

Fuel Volatility

Diesel swings threaten route economics and margin.

Labour Shortage

CDL gaps force costly spot buys and deferred loads.

E-Com Pressure

Same-day/curbside surge strains pick, stage and delivery slots.

Sustainability Push

EV pilots need carbon-aware route and range planning.

Locus' End-to-End Toolkit for Publix

Build cost-efficient, capacity-aware routes across home-delivery, curbside and BOPIS drops, respecting frozen/chilled constraints and two-hour windows.

Query live fleet capacity and surface only feasible same-day/next-day slots on site and app. Cart conversion rises; OTIF stays >98 %.

Auto-assign orders to the right reefer zone or insulated tote, stream temps live and alert on breaches before product quality slips.

ShipFlex blends Publix tractors, crowd-sourced drivers and parcel partners per order—balancing cost, SLA risk and ZIP-code reach on the fly.

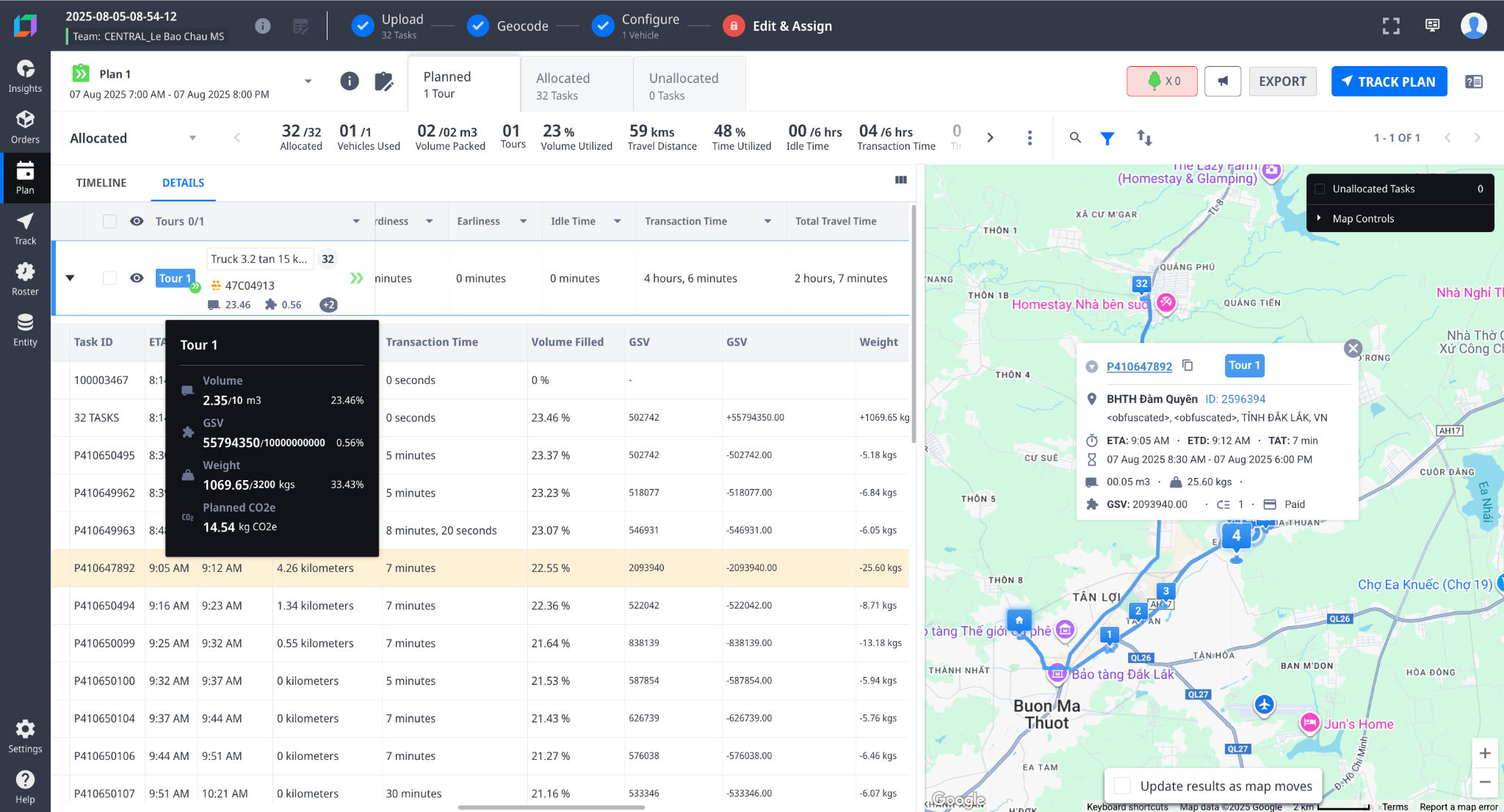

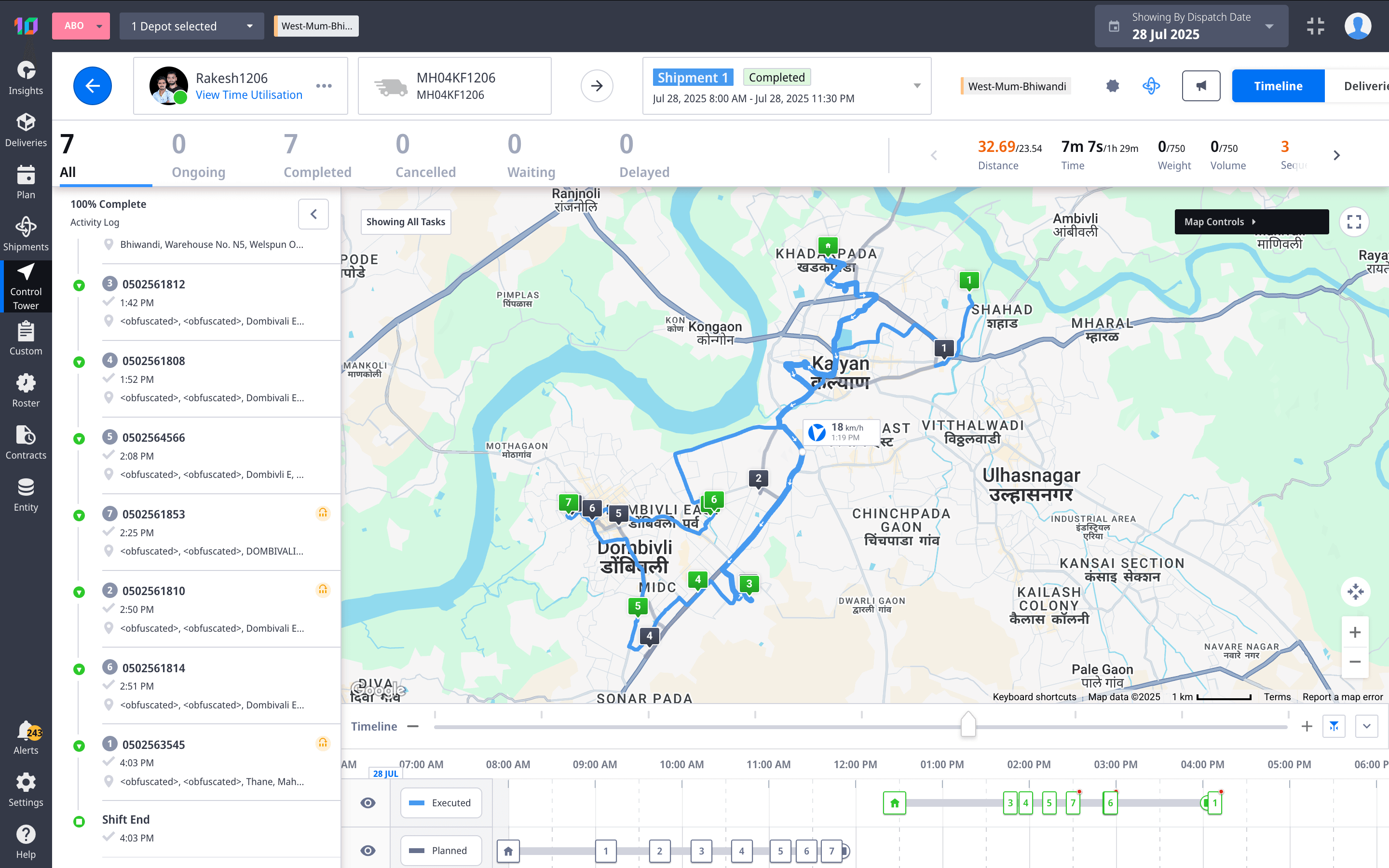

Ops teams watch every load on one map; auto-alerts for delays, route deviations or capacity overruns trigger proactive reroutes and customer pings.

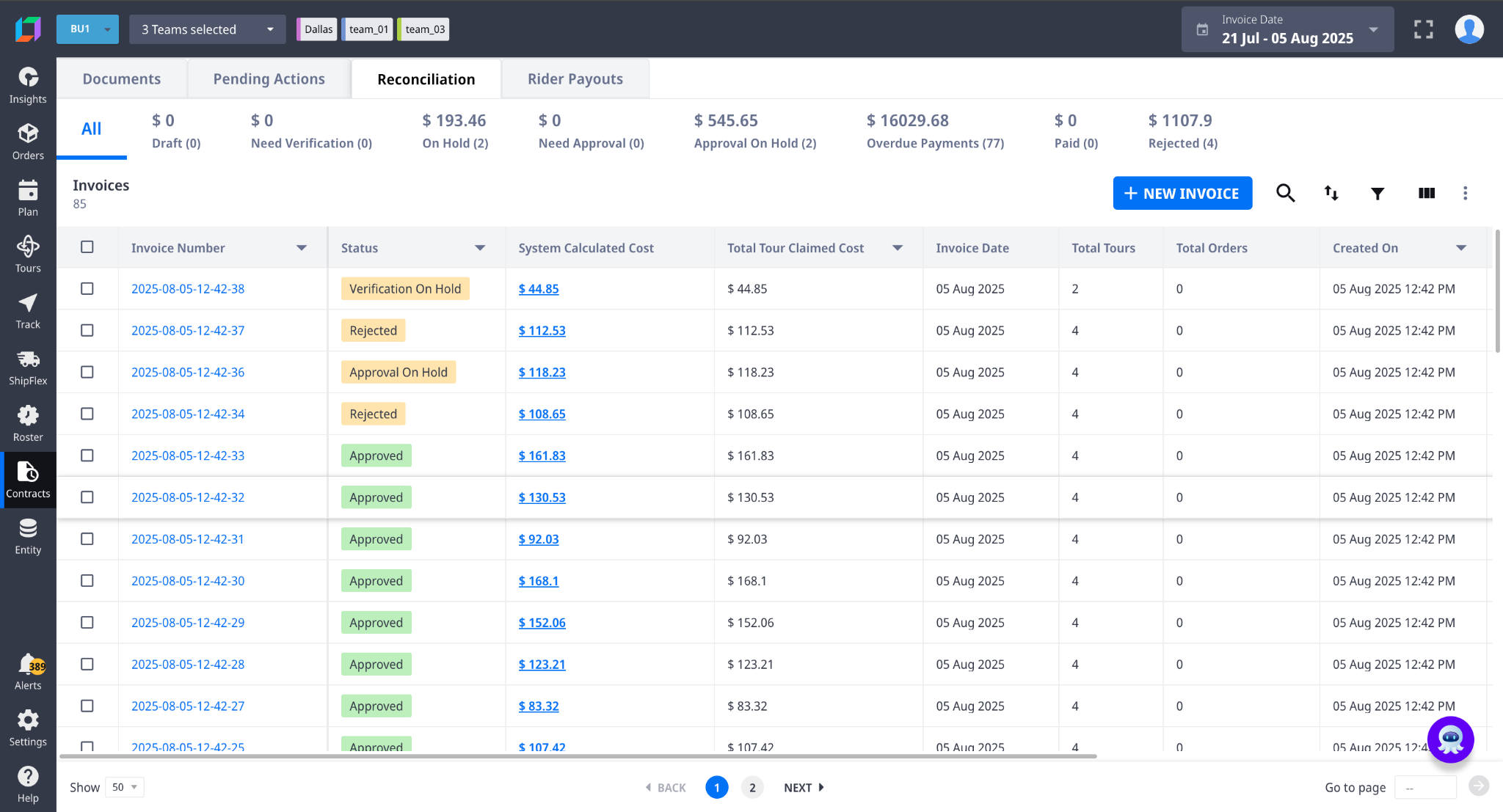

Planned vs actual miles, stops and accessorials sync to finance instantly, flagging over-billing and slashing audit hours.

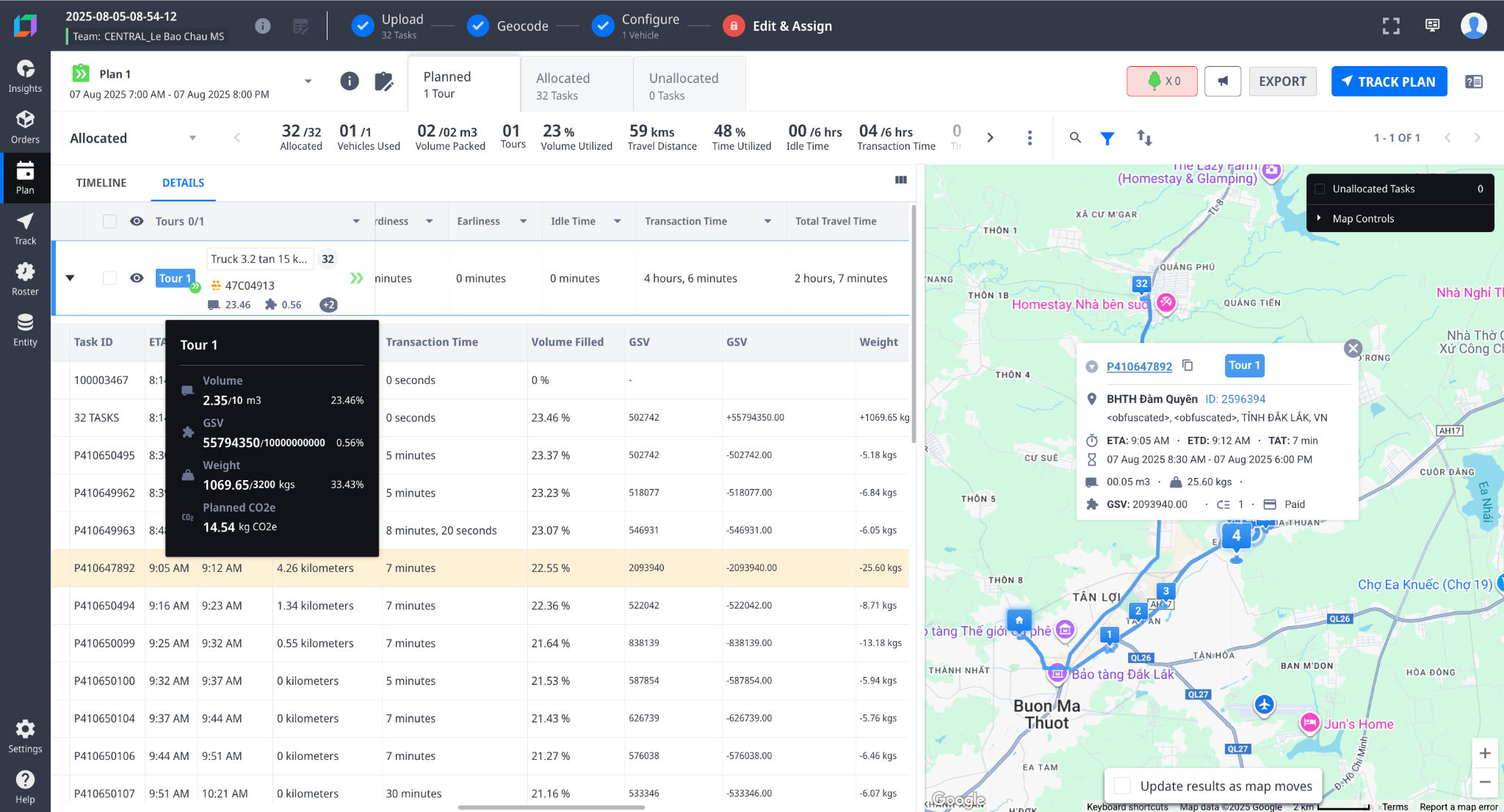

Route Optimisation

Build cost-efficient, capacity-aware routes across home-delivery, curbside and BOPIS drops, respecting frozen/chilled constraints and two-hour windows.

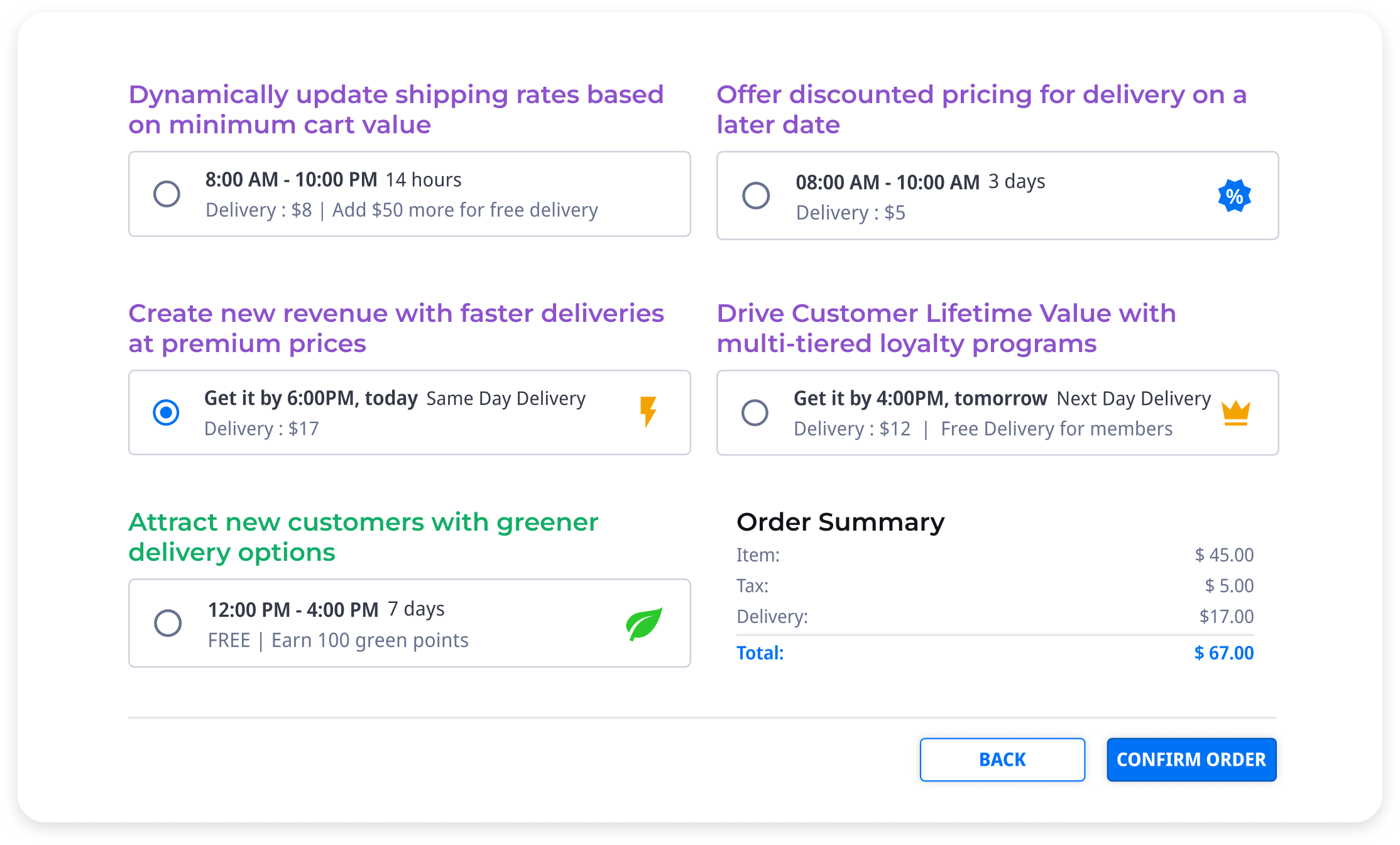

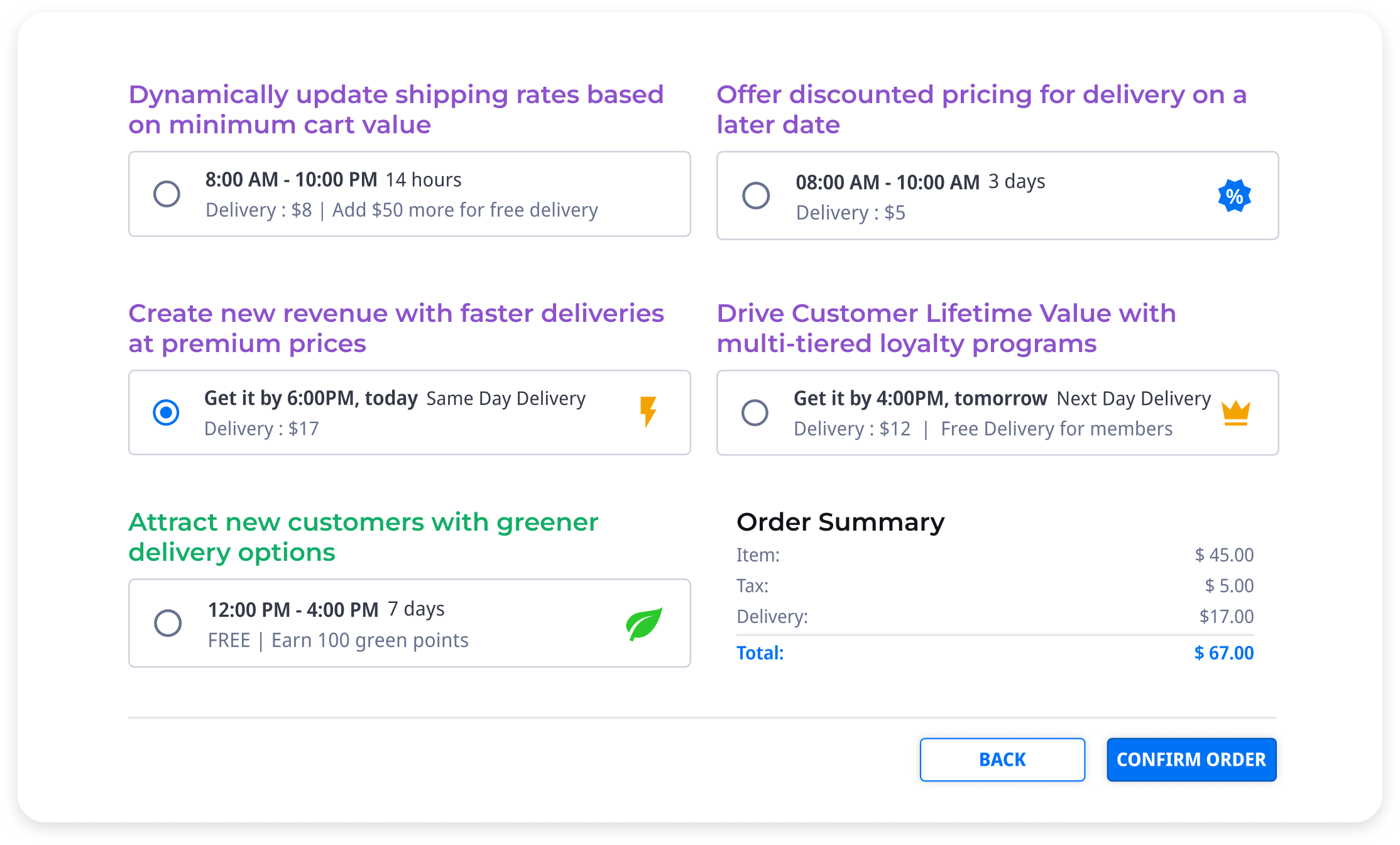

Delivery Linked Checkout

Query live fleet capacity and surface only feasible same-day/next-day slots on site and app. Cart conversion rises; OTIF stays >98 %.

Temperature-Control & Freshness Monitoring

Auto-assign orders to the right reefer zone or insulated tote, stream temps live and alert on breaches before product quality slips.

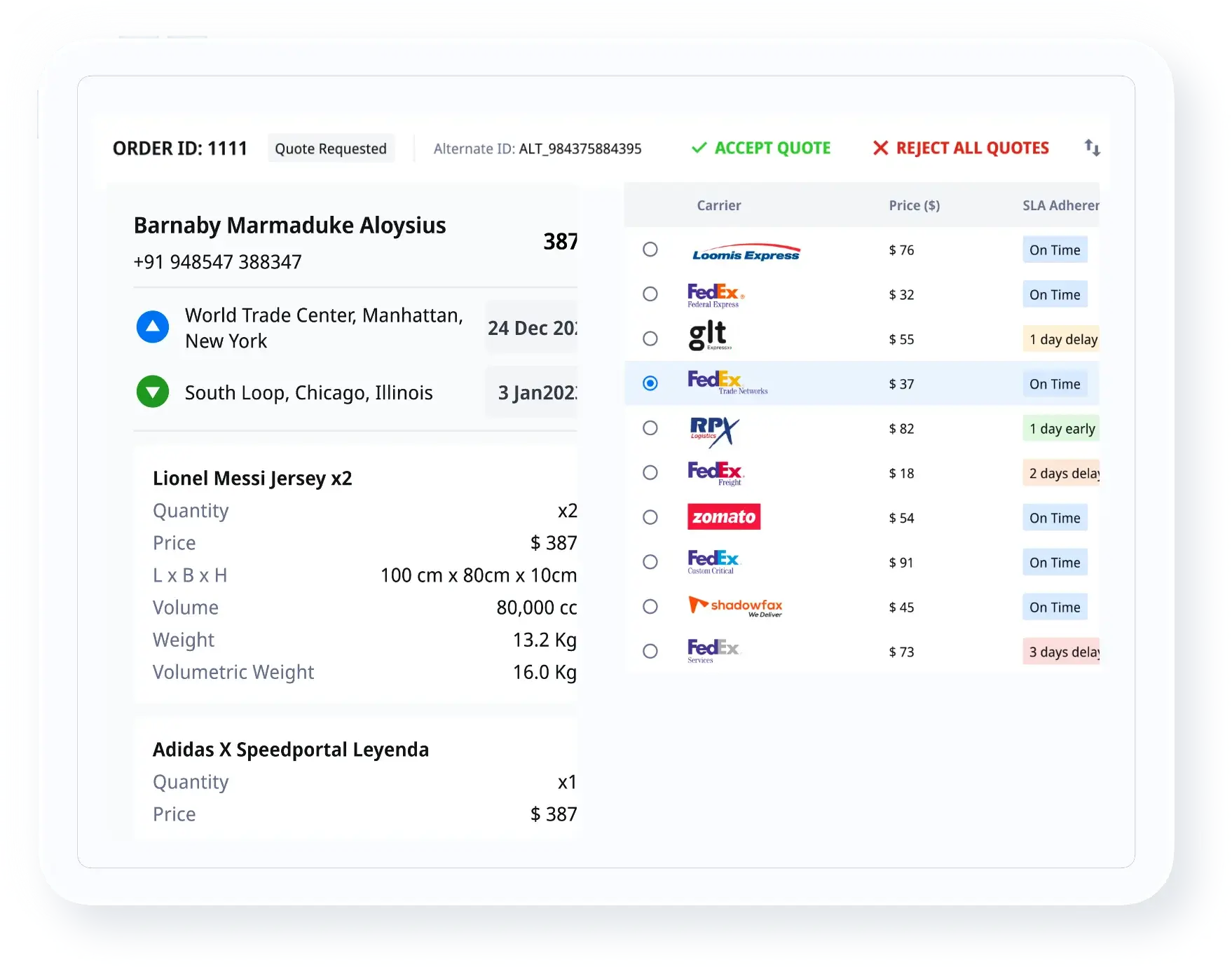

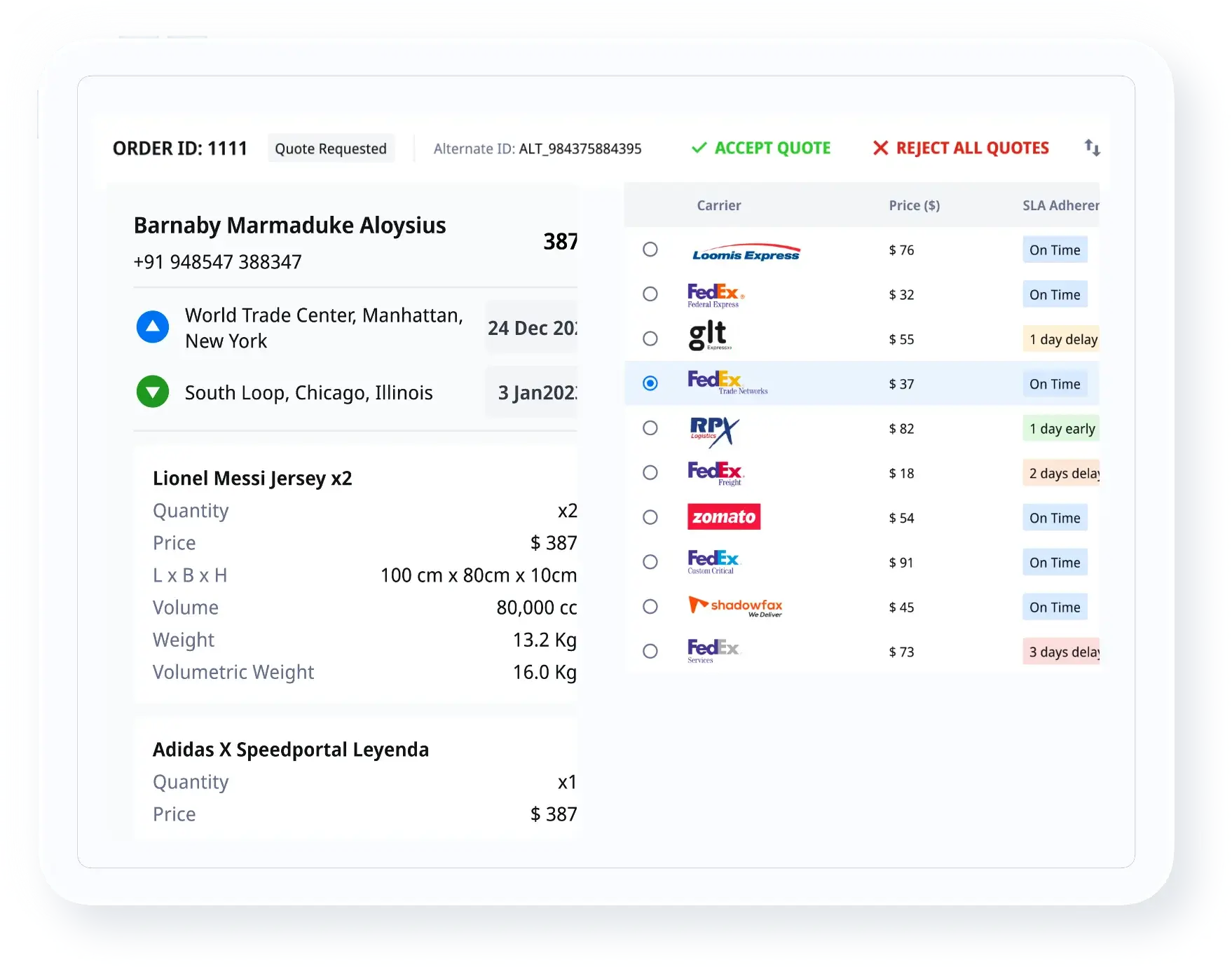

Dynamic Carrier Selection

ShipFlex blends Publix tractors, crowd-sourced drivers and parcel partners per order—balancing cost, SLA risk and ZIP-code reach on the fly.

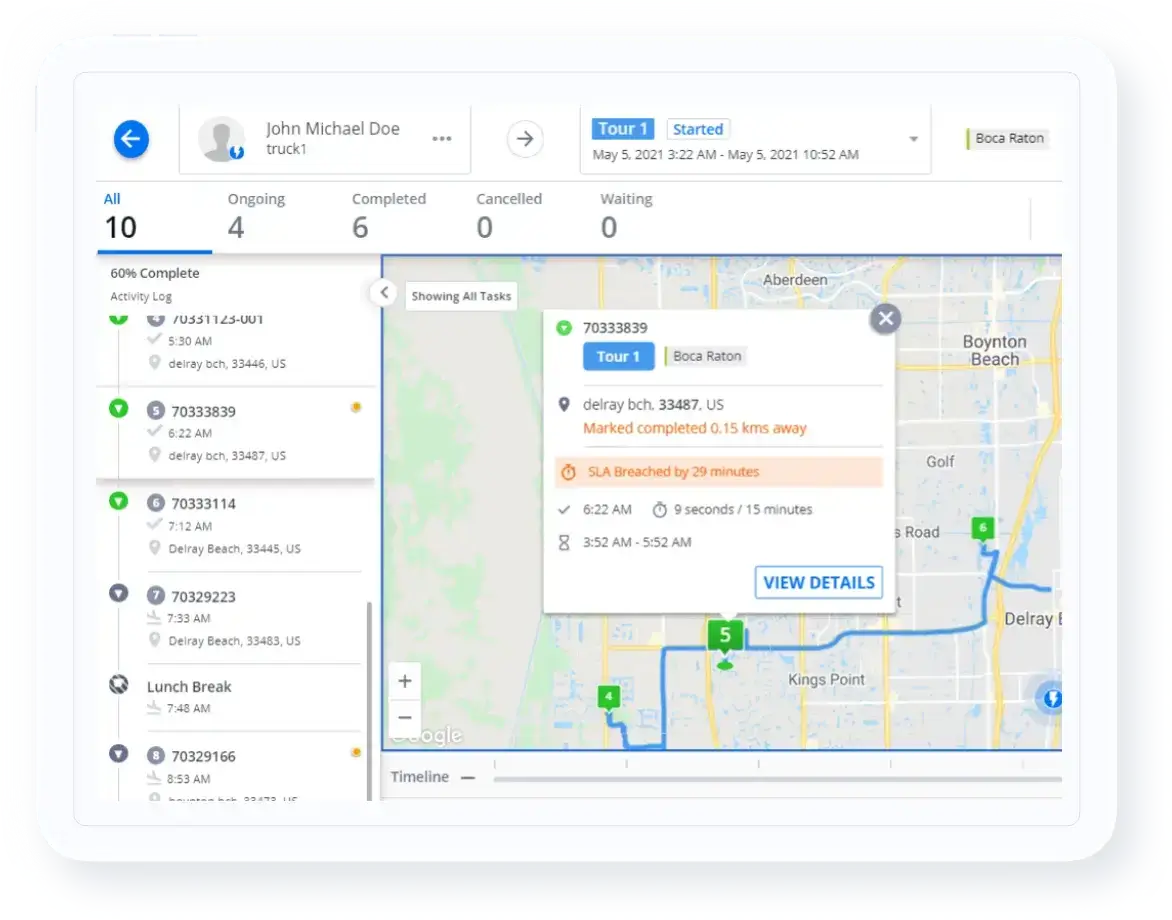

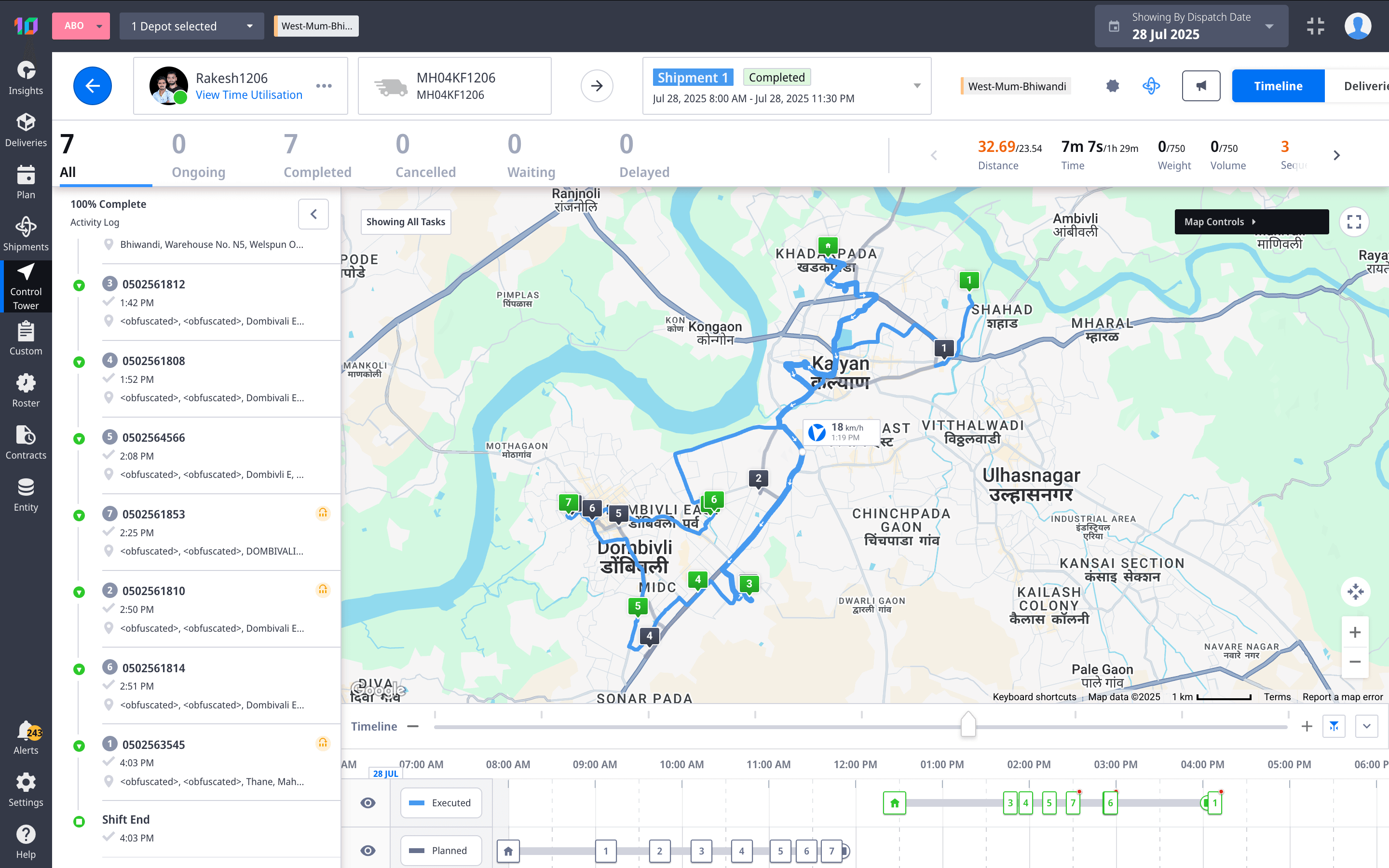

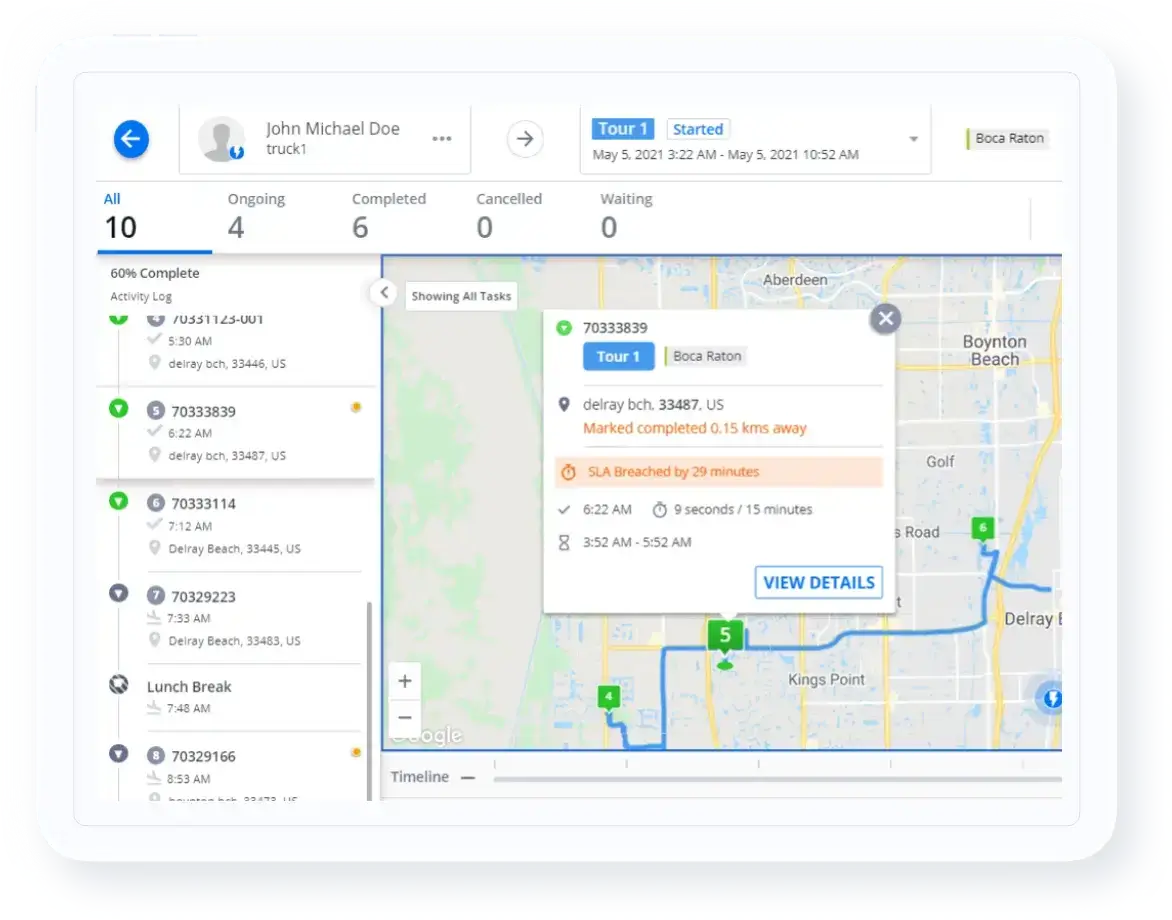

Control Tower

Ops teams watch every load on one map; auto-alerts for delays, route deviations or capacity overruns trigger proactive reroutes and customer pings.

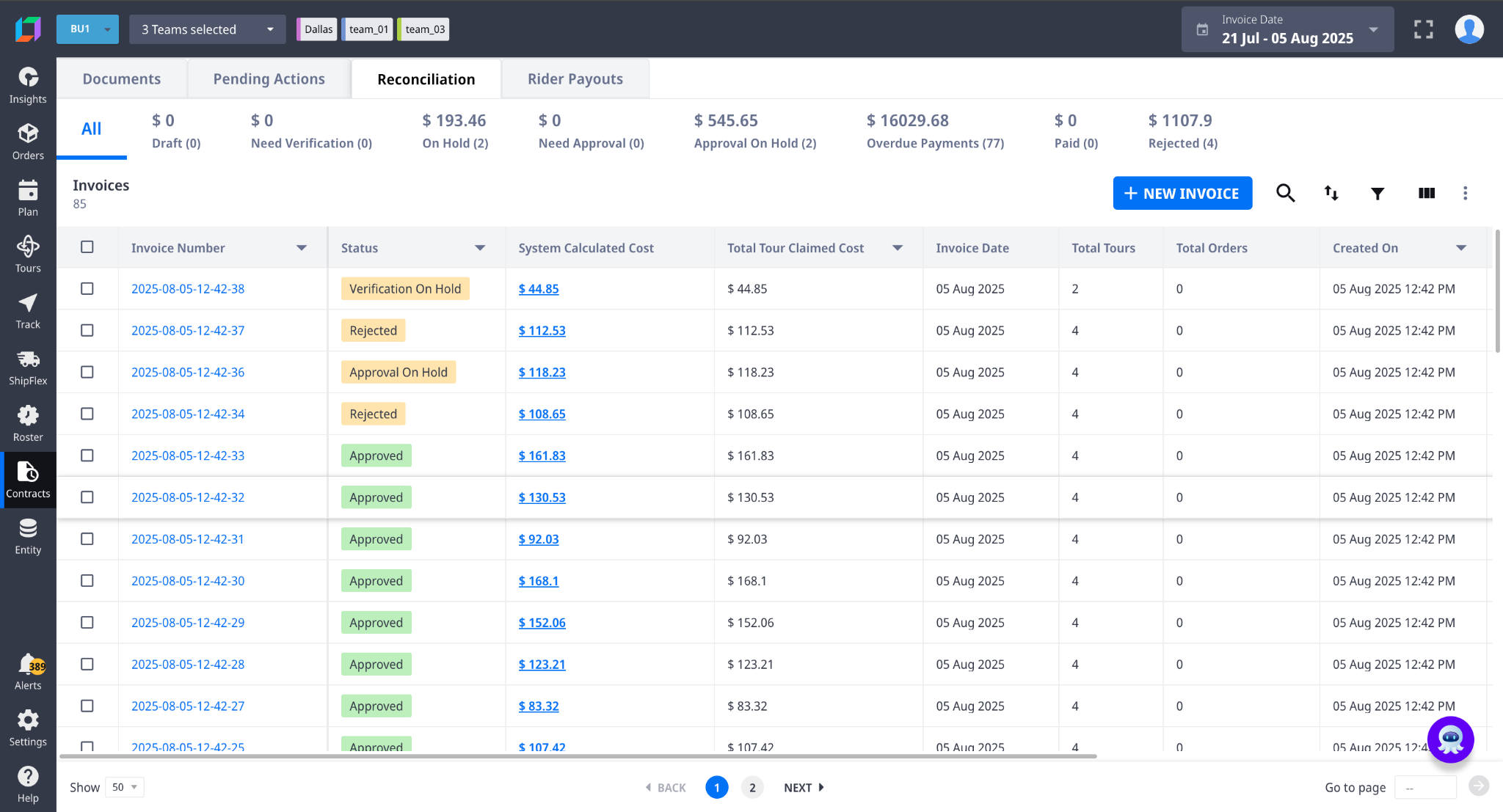

Automated Carrier Invoice Reconciliation

Planned vs actual miles, stops and accessorials sync to finance instantly, flagging over-billing and slashing audit hours.

Success Stories

Enabling ShipFlex For Goodfood

ShipFlex unified Goodfood’s 3PL networks into a single dashboard, automating carrier selection and real-time order tracking for smoother, faster fulfillment.

Increase in order frequency

Reduction in fufilment costs

Reduction in fulfilment time due to switch to 3PLs

Reduction in man hours spent on manual actions

Latest Locus Insights

Locus for Retail: Shippers’ One Stop Shop for All Third Party Carrier Woes

A Look at the Future of Grocery Retail in North America