End-to-End Logistics Optimization for Panda Retail

AI-optimized logistics that cut kilometres, lift OTIF and keep expansion on schedule across 40 Saudi cities, from Riyadh hypermarkets to the Kingdom’s most remote stores.

Locus Market Recognition From Gartner For 5 Consecutive Years

See Locus in Action — For Panda Retail

Chosen by global brands in 30+ countries over the last decade

The Logistics Challenges Facing Panda Retail Today

As KSA's largest grocery retailer, your expansion brings complex operational challenges that traditional methods can't solve.

Rural Distance

500 km trunk runs to remote cities push cost-to-serve up and delay first drops.

Last-Mile Gaps

Fast-growing e-commerce struggles with messy addresses and unoptimised delivery slots.

Ramadan Spike

Throughput surges 1.5×, overloading DC docks and driver rosters.

Fleet Utilisation

500+ refrigerated trucks need smarter dispatch to avoid empty back-hauls and idle time.

Data Blind-spots

TMS, WMS, and fleet telematics don’t share a single, real-time view, and exceptions surface late.

Store-Launch Load

20 new stores demand predictive capacity planning and route modelling months ahead.

Solutions Built for Panda’s Reality

We knit every DC, dark store and pharmacy shelf into a single, real-time inventory graph. The optimizer automatically assigns each web, app or call-centre order to the node that can fulfil it fastest at the lowest cost. Fill-rates climb, split-ships disappear and walk-in customers never face an empty shelf.

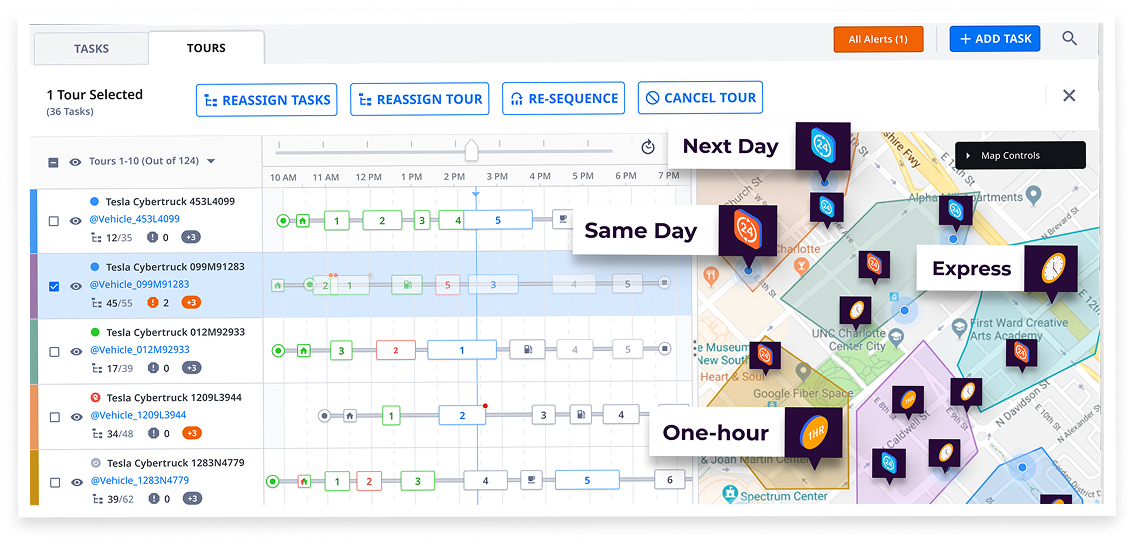

The moment an order is confirmed, our engine weighs vehicle availability, traffic, driver skillset and refrigeration needs, then dispatches from the best-placed store, hub or cross-dock. Whether the promise is same-day in Jeddah or a two-hour slot in Yanbu, routes stay live and reshuffle whenever reality changes.

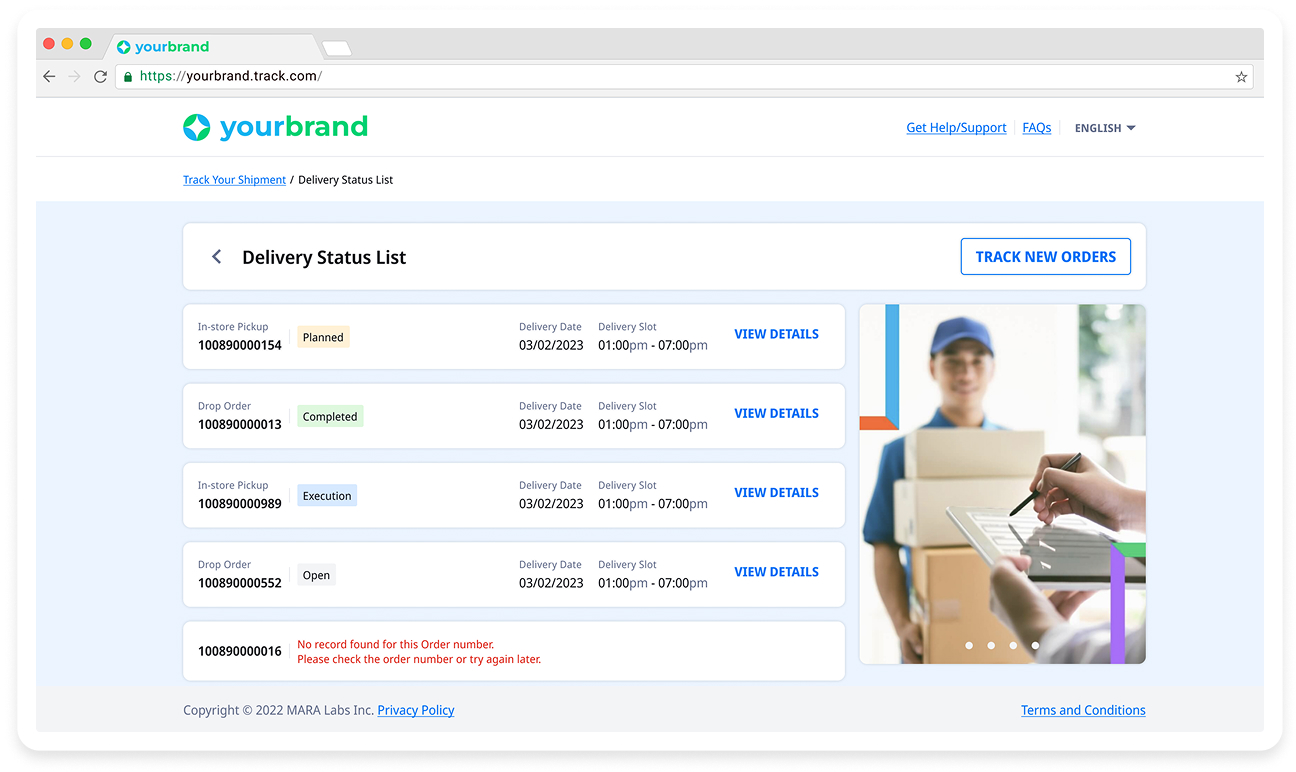

At checkout we verify every location against national address APIs, GPS and What3Words. Only delivery windows that the fleet can physically meet are displayed. That single step slashes first-attempt failures, call-centre escalations and wasted rider mileage.

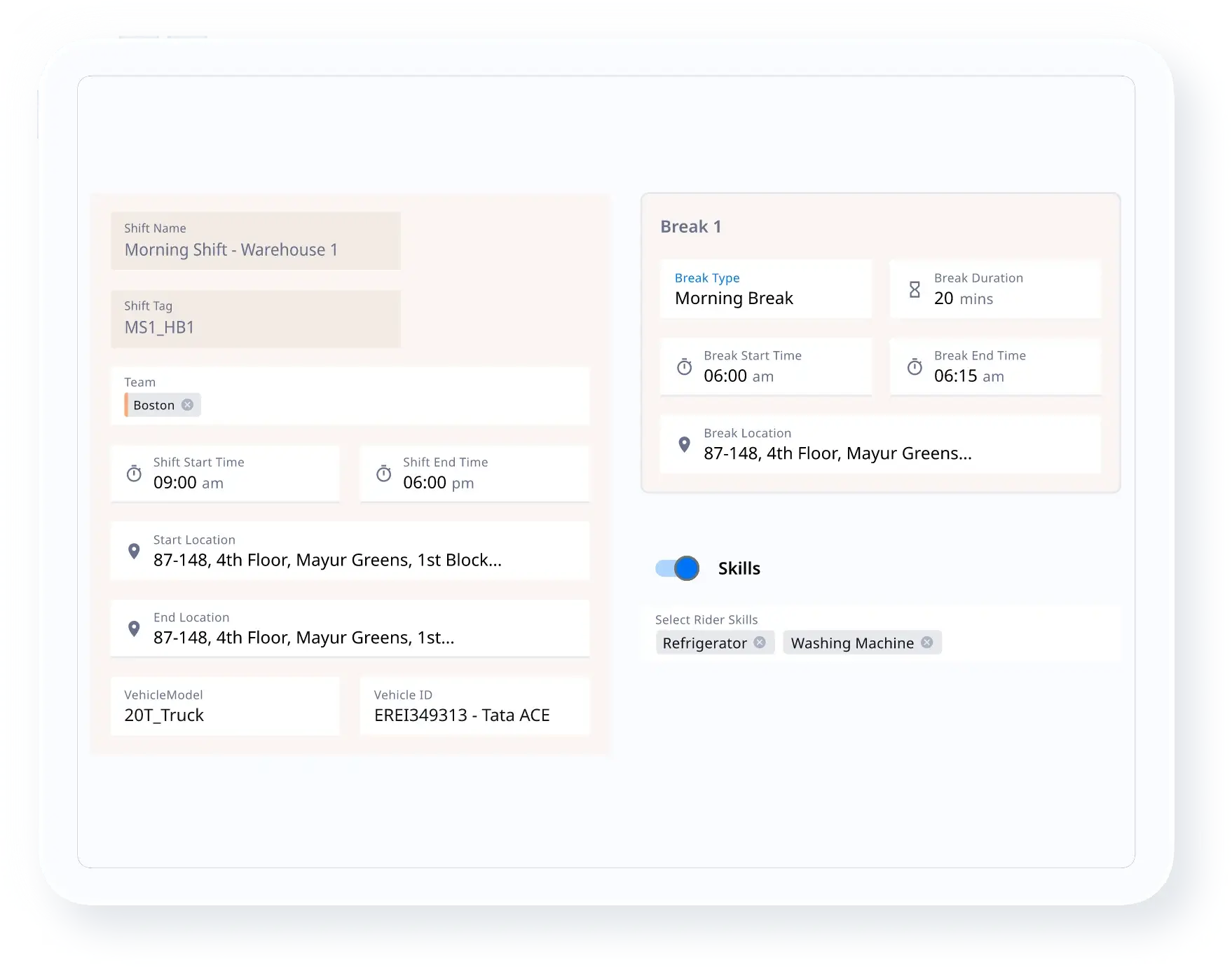

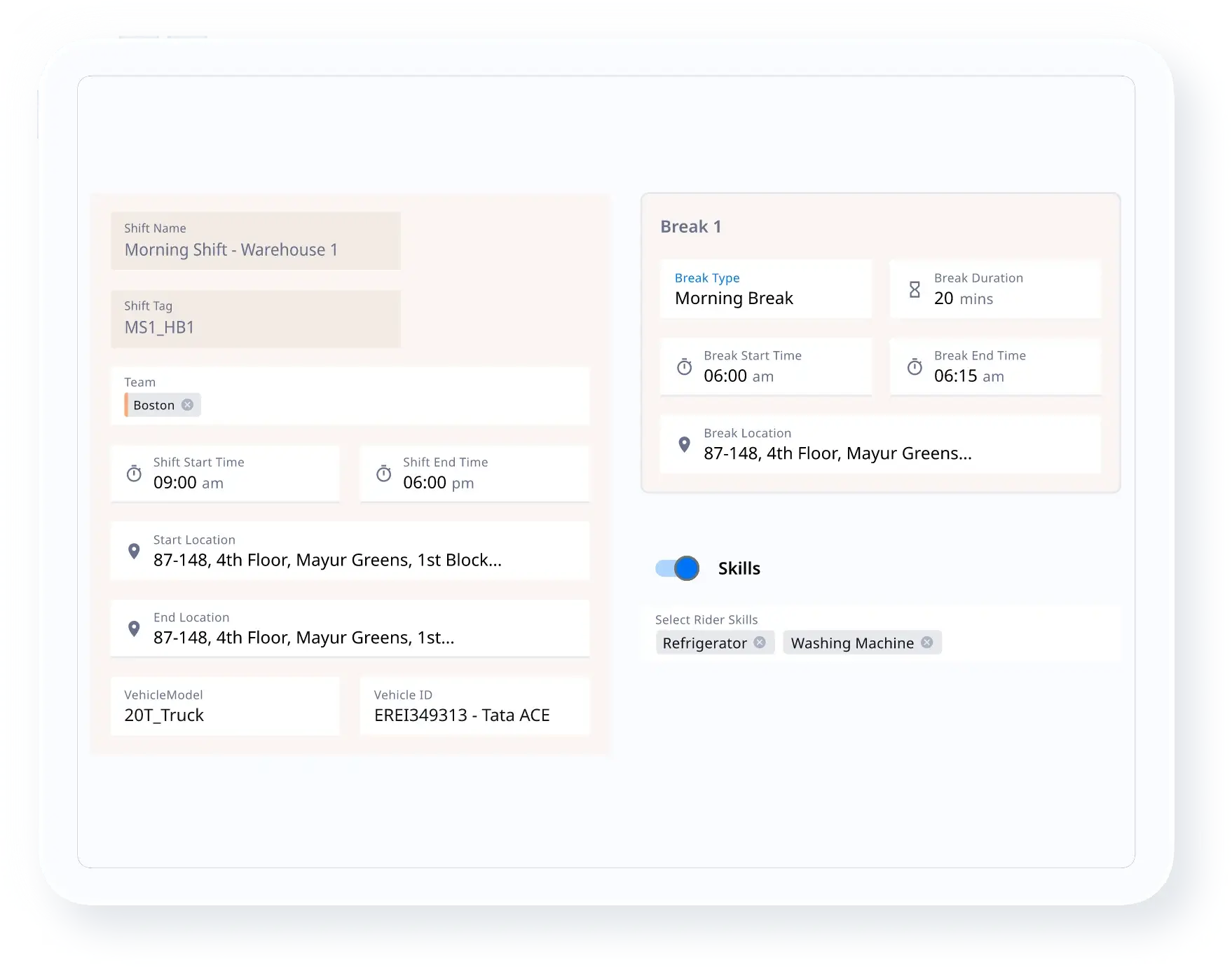

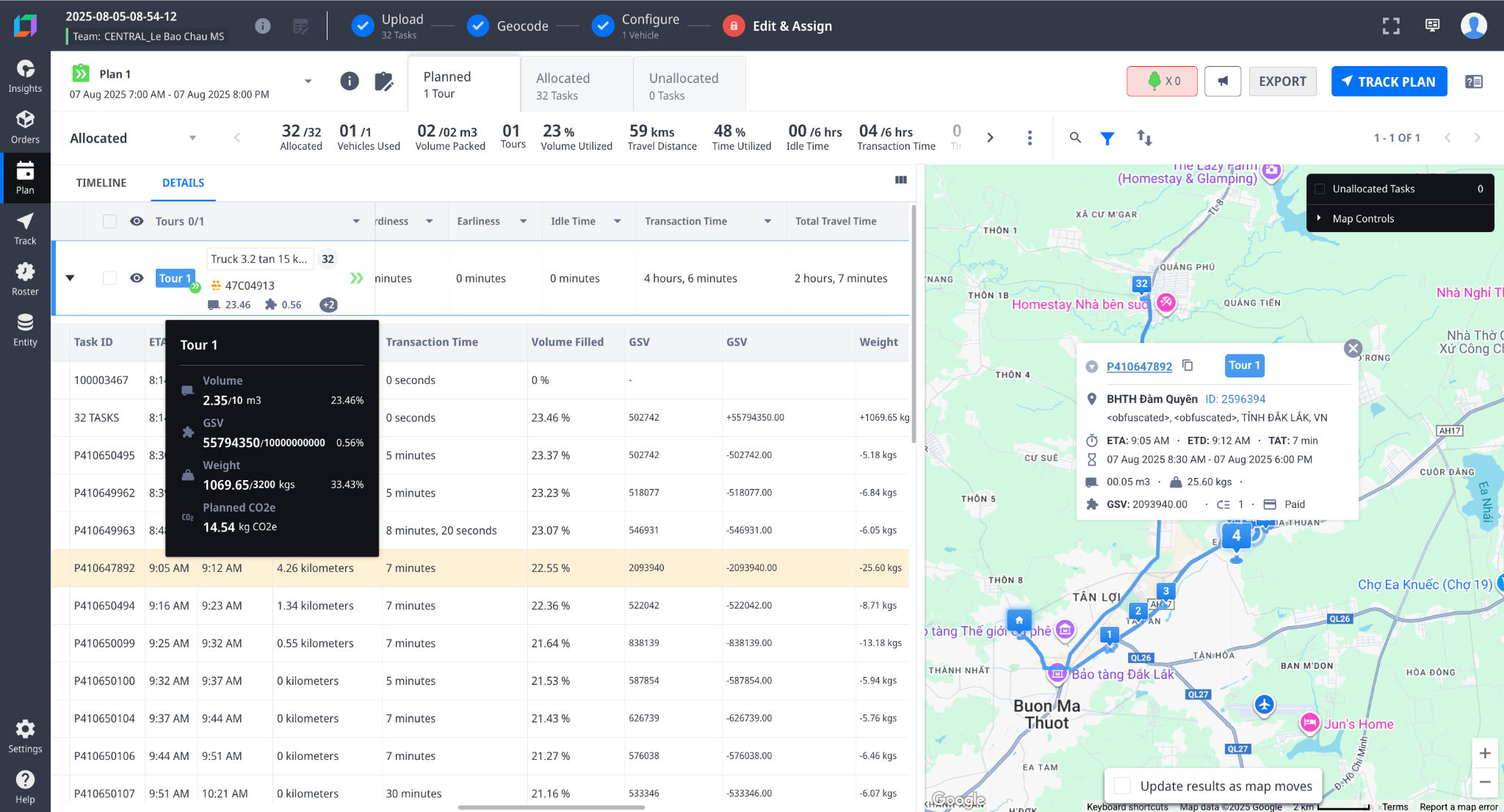

Every pallet, tote and cooler box is sequenced to hit maximum cube fill and minimum kilometres. The optimiser factors driver hours, prayer times, parking constraints and CO₂ per kilometre — then re-optimises on the fly when a truck is delayed or a DC wave overruns.

Returns, damaged-goods pickups and empty-crate loops feed into the same algorithm that handles outbound. Failed deliveries are auto-bundled onto nearby runs, spare van capacity is monetised for backhauls, and kilometres driven without revenue drop sharply.

Dense urban districts get a “60-minute guarantee” by routing from the closest Panda Express or dark store, not a distant DC. Real-time order pooling and bike-friendly routing shrink both lead-time and last-mile emissions.

Customers can choose a speed-versus-cost (or sustainability) slider at checkout. Behind the scenes, the engine throttles slot availability up or down by zone, load-factor and forecast demand, keeping OTIF high while smoothing peak pressure on fleet and labour.

Omnichannel Fulfilment

We knit every DC, dark store and pharmacy shelf into a single, real-time inventory graph. The optimizer automatically assigns each web, app or call-centre order to the node that can fulfil it fastest at the lowest cost. Fill-rates climb, split-ships disappear and walk-in customers never face an empty shelf.

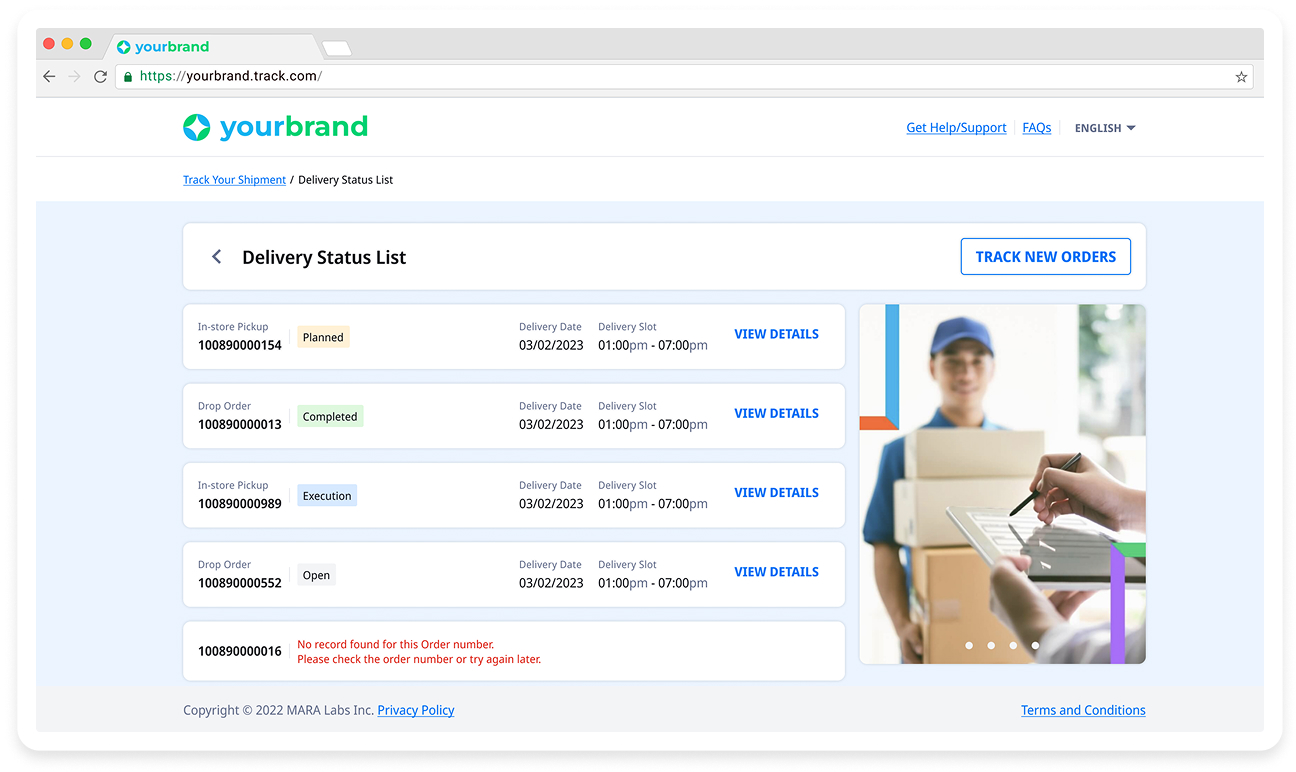

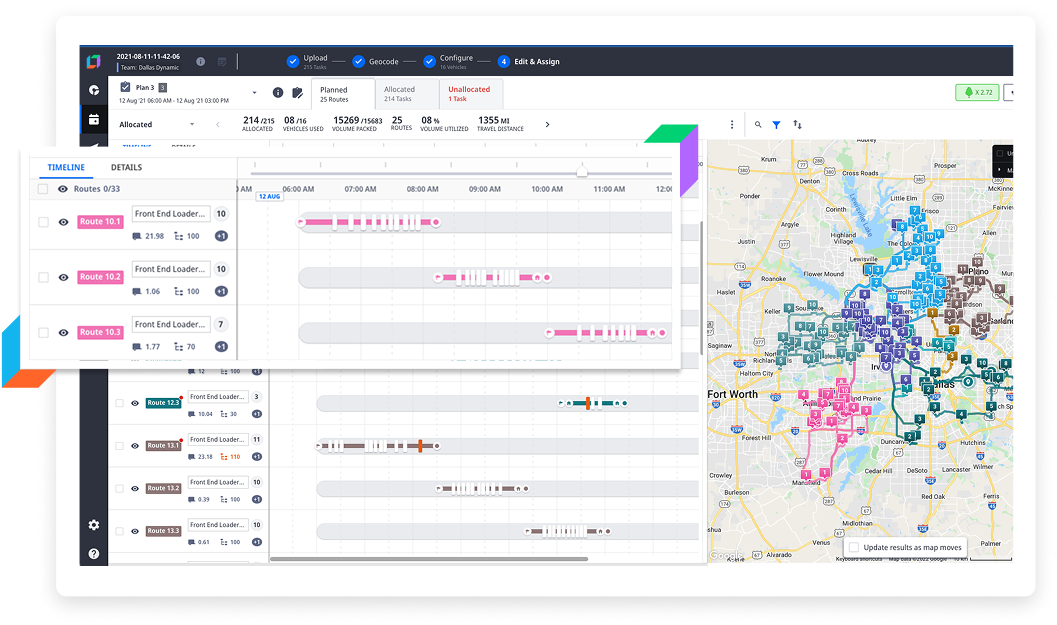

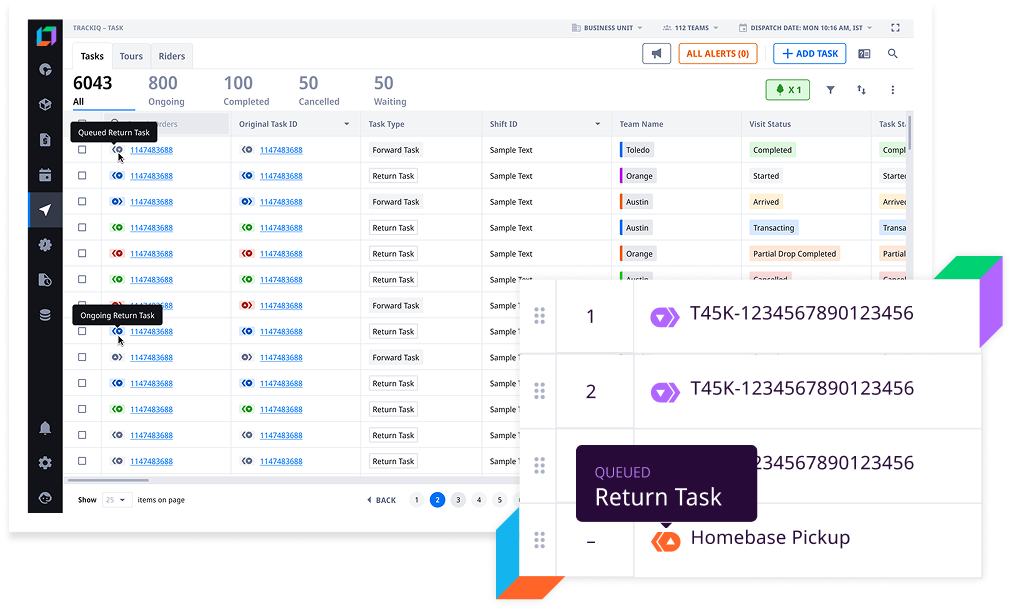

Dynamic Last-Mile Delivery

The moment an order is confirmed, our engine weighs vehicle availability, traffic, driver skillset and refrigeration needs, then dispatches from the best-placed store, hub or cross-dock. Whether the promise is same-day in Jeddah or a two-hour slot in Yanbu, routes stay live and reshuffle whenever reality changes.

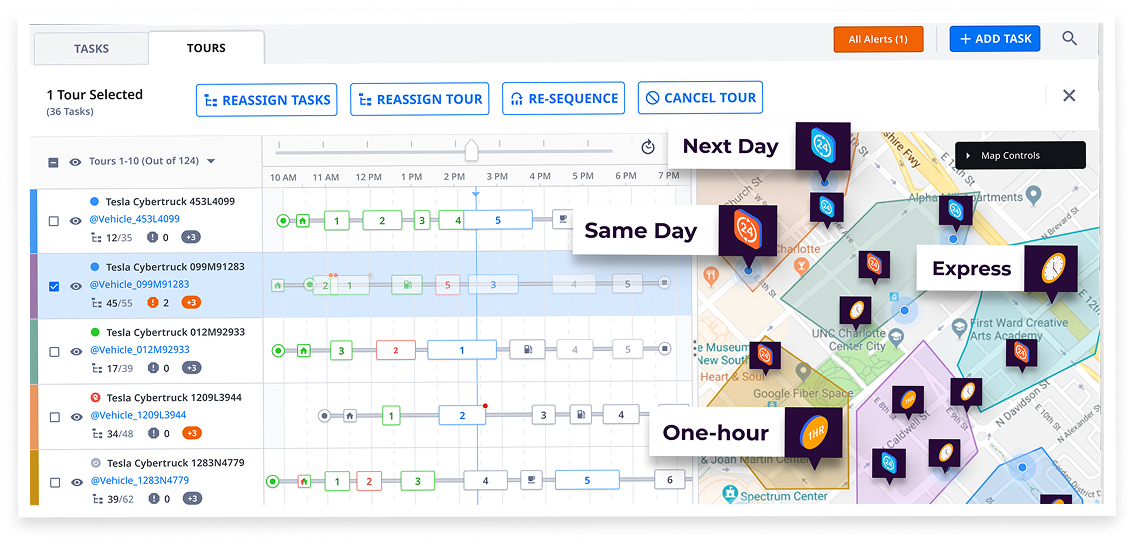

Address & Slot Verification

At checkout we verify every location against national address APIs, GPS and What3Words. Only delivery windows that the fleet can physically meet are displayed. That single step slashes first-attempt failures, call-centre escalations and wasted rider mileage.

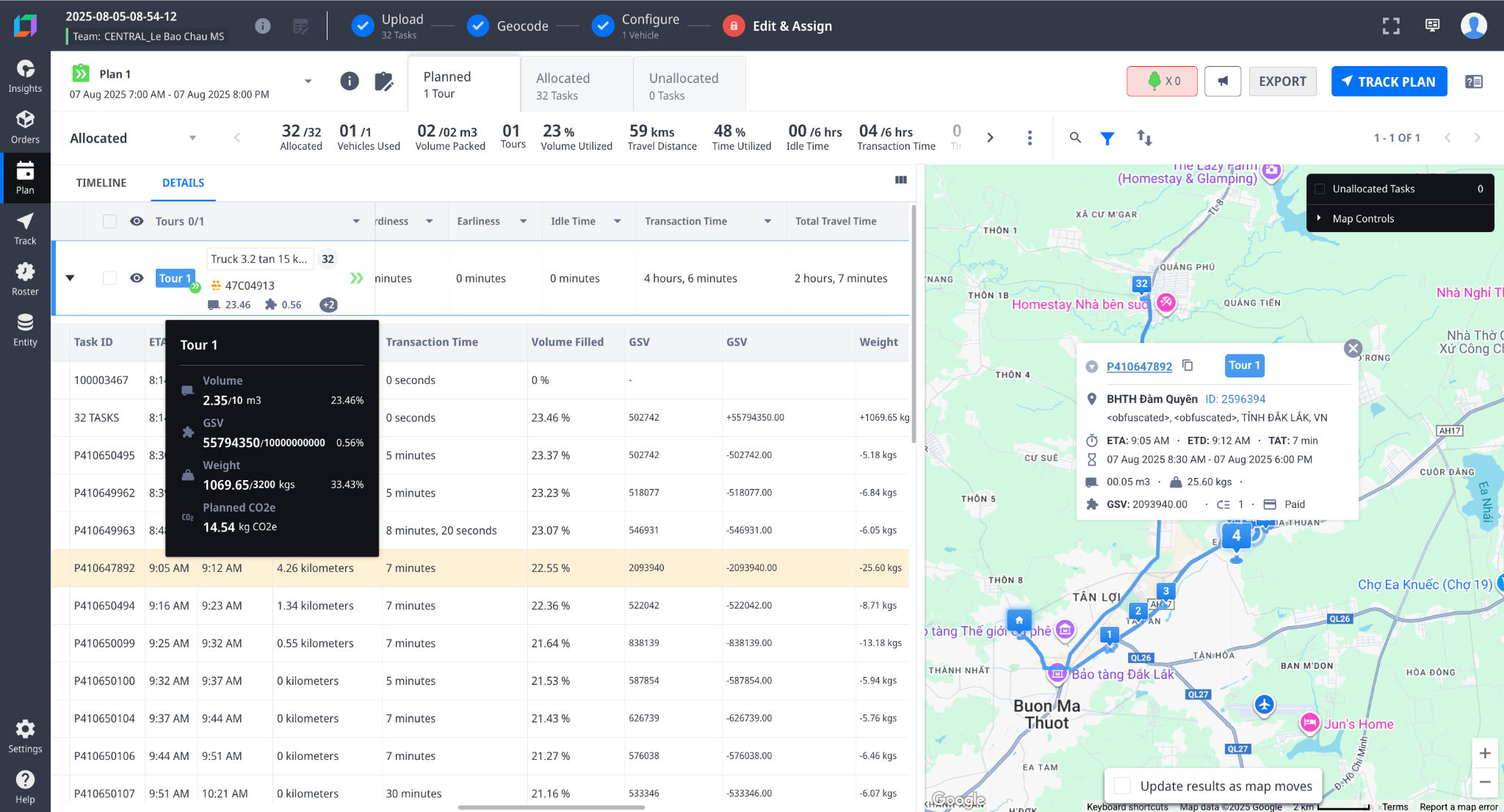

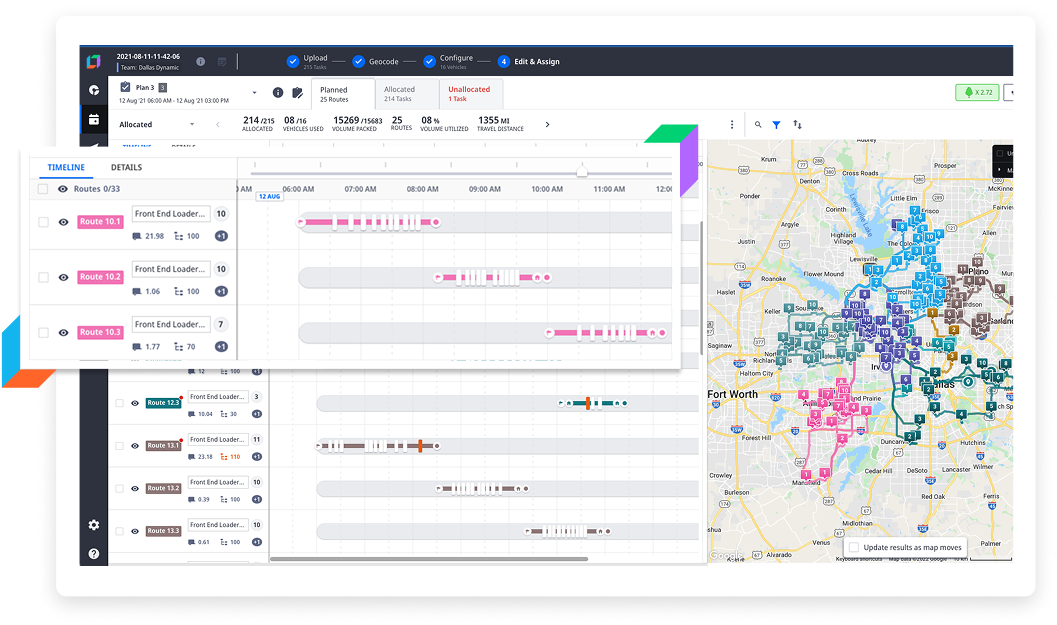

Route Optimisation

Every pallet, tote and cooler box is sequenced to hit maximum cube fill and minimum kilometres. The optimiser factors driver hours, prayer times, parking constraints and CO₂ per kilometre — then re-optimises on the fly when a truck is delayed or a DC wave overruns.

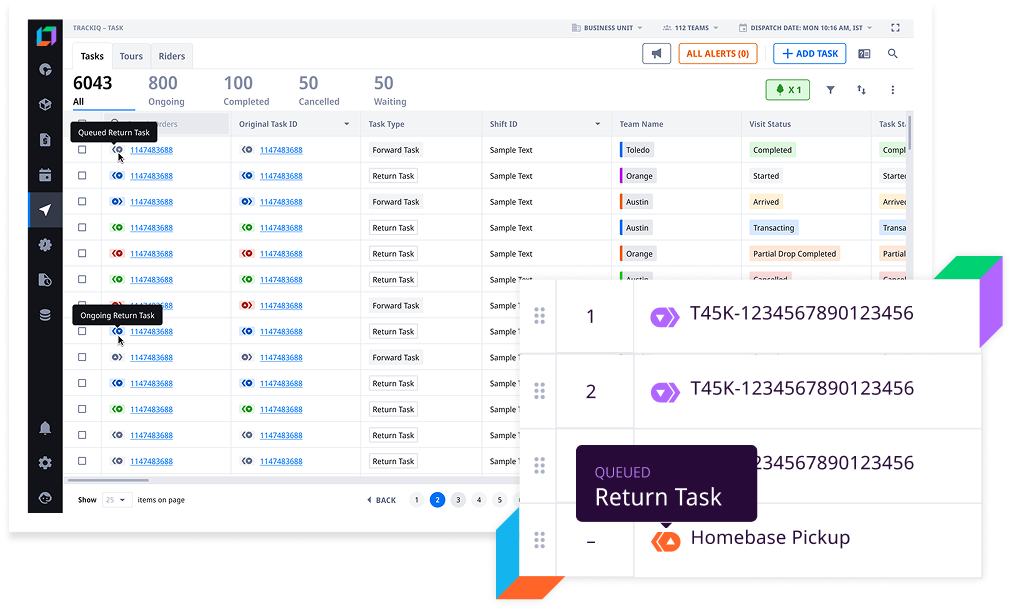

Reverse-Logistics Automation

Returns, damaged-goods pickups and empty-crate loops feed into the same algorithm that handles outbound. Failed deliveries are auto-bundled onto nearby runs, spare van capacity is monetised for backhauls, and kilometres driven without revenue drop sharply.

Hyperlocal Delivery Planning

Dense urban districts get a “60-minute guarantee” by routing from the closest Panda Express or dark store, not a distant DC. Real-time order pooling and bike-friendly routing shrink both lead-time and last-mile emissions.

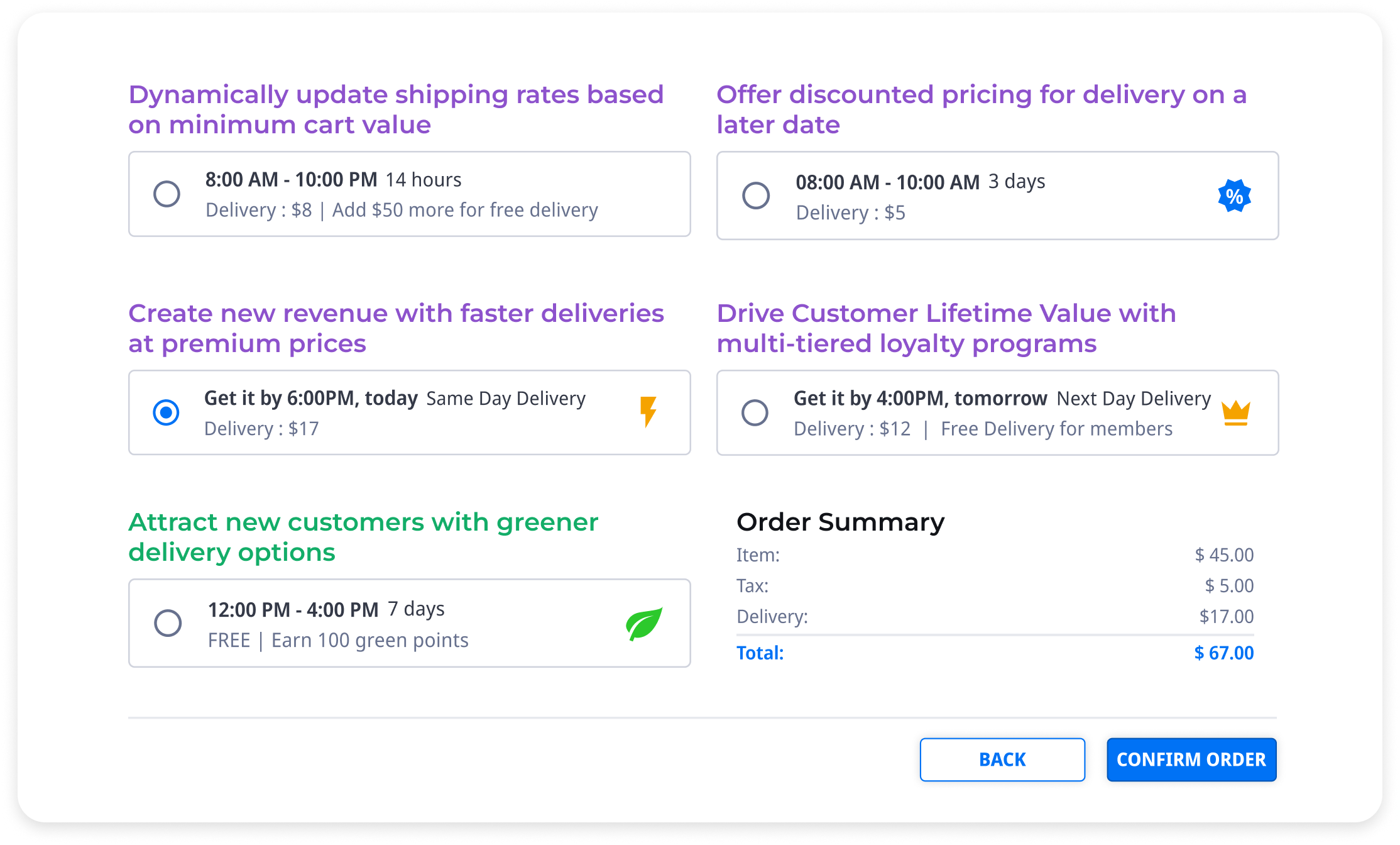

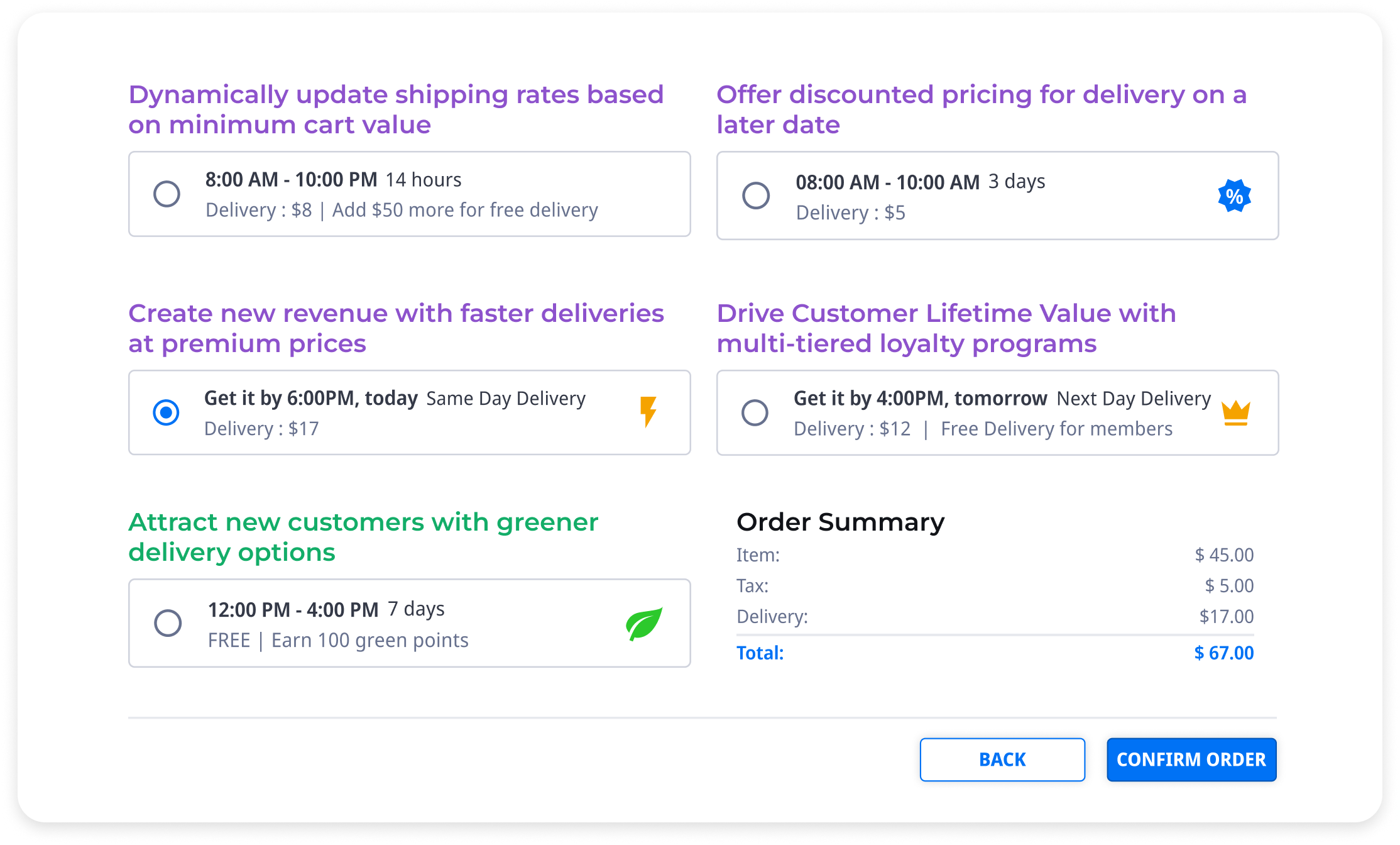

Flexible Slot Management

Customers can choose a speed-versus-cost (or sustainability) slider at checkout. Behind the scenes, the engine throttles slot availability up or down by zone, load-factor and forecast demand, keeping OTIF high while smoothing peak pressure on fleet and labour.

Success Stories

"With Locus' ShipFlex, we are looking to streamline third-party deliveries with rich carrier integrations, real-time tracking and more onto a single dashboard. This enables us to take full control of our third-party order-to-delivery process, operate more efficiently, and ensure timely deliveries, resulting in an enhanced customer experience."

Advanced Route Optimization

For Lulu International

Automated route planning and integrated driver scheduling boosted fleet utilization and delivery-window accuracy across Lulu International’s 239 GCC hypermarkets.

SLA Adherence

In fleet size

Plan run time 30-40 min/slot

to 5 min

In fuel savings

Latest Locus Insights

Optimizing the final stretch: A study of unit economics in last-mile delivery

Hope Comes in the form of AI for Big-Box Stores