Keep Menards Trusted — Fast, Across 300+ Midwest Stores

AI-optimised logistics that keep every lumber load and seasonal SKU in-stock from new Ravenna OH hubs to the furthest job site.

Locus Market Recognition From Gartner For 5 Consecutive Years

See Locus in Action — For Menards

Chosen by global brands in 30+ countries over the last decade

The Logistics Challenges Facing Menards Today

Midwest Sprawl

300+ stores across 15 states need smarter lane design to trim stem-miles and protect in-stock levels.

Empty Backhauls

Drop-trailer runs leave private rigs returning light, wasting miles and driving up diesel and carbon costs.

DC Start-Up Risk

Ravenna OH and upcoming PA hubs require dynamic rerouting and capacity modeling to prevent launch-week stockouts.

OTIF Penalties

10 % fines for late supplier loads call for real-time ETA dashboards and auto-re-slotting when delays surface.

Peak-Season Bottlenecks

Spring project surge doubles outbound loads, straining yard turns, driver HOS, and delivery windows.

Siloed Carrier Data

Private fleet and “preferred” carriers run on separate systems, masking true cost-per-mile and hindering live decisions.

Solutions Built for Menards’ Reality

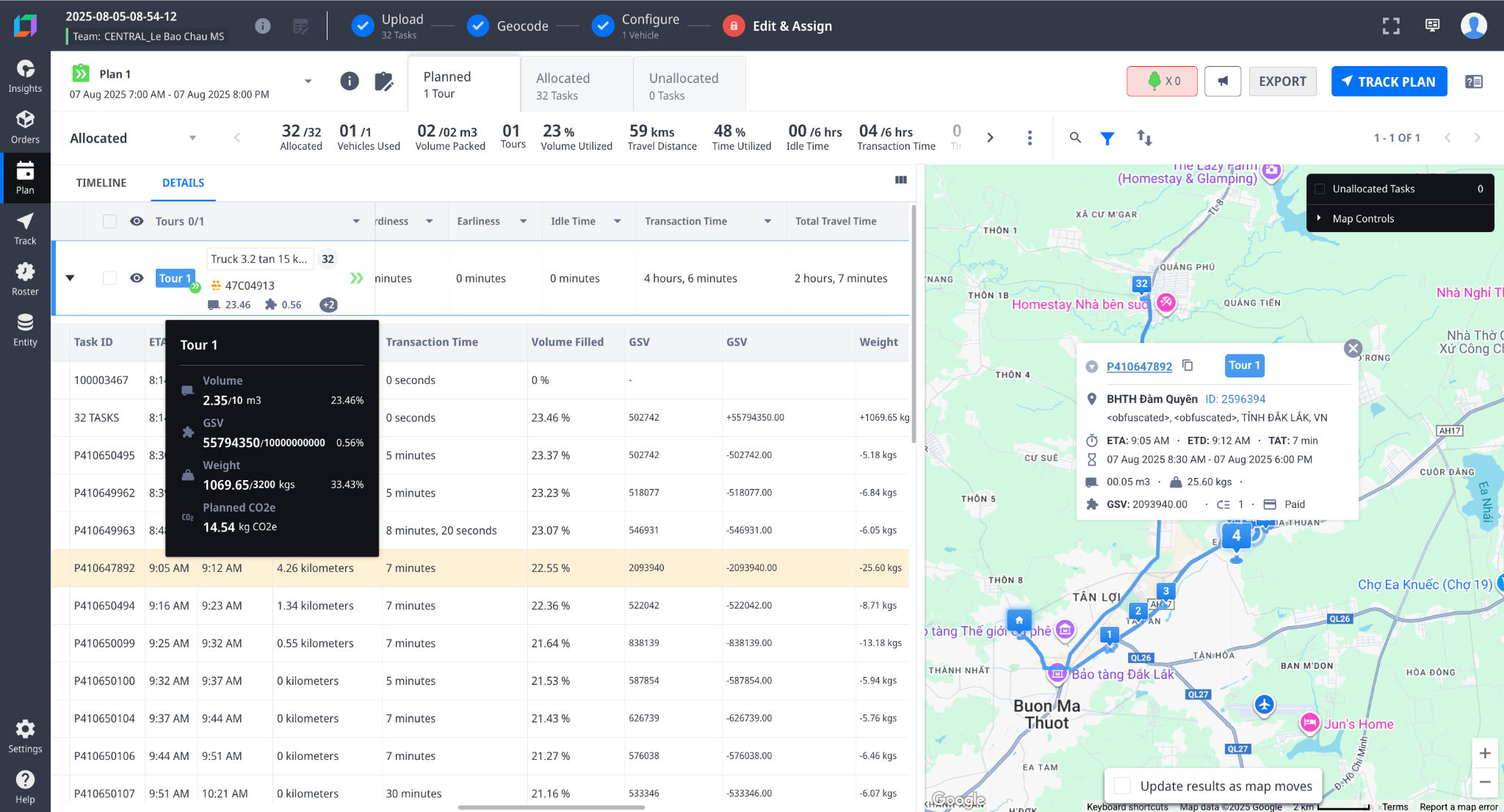

Build cube/weight-balanced, multi-stop routes for lumber, drywall, and seasonal goods heading to stores and job sites, trimming empty miles while honoring lift-gate or boom-crane constraints.

Auto-elevate urgent job-site drops when crews are waiting, reshuffling lower-priority stops so critical materials still arrive on time without adding trucks.

Use ShipFlex to allocate each load to the optimal DC, cross-dock, flatbed, or LTL partner, balancing cost, capacity, and oversized-item handling needs.

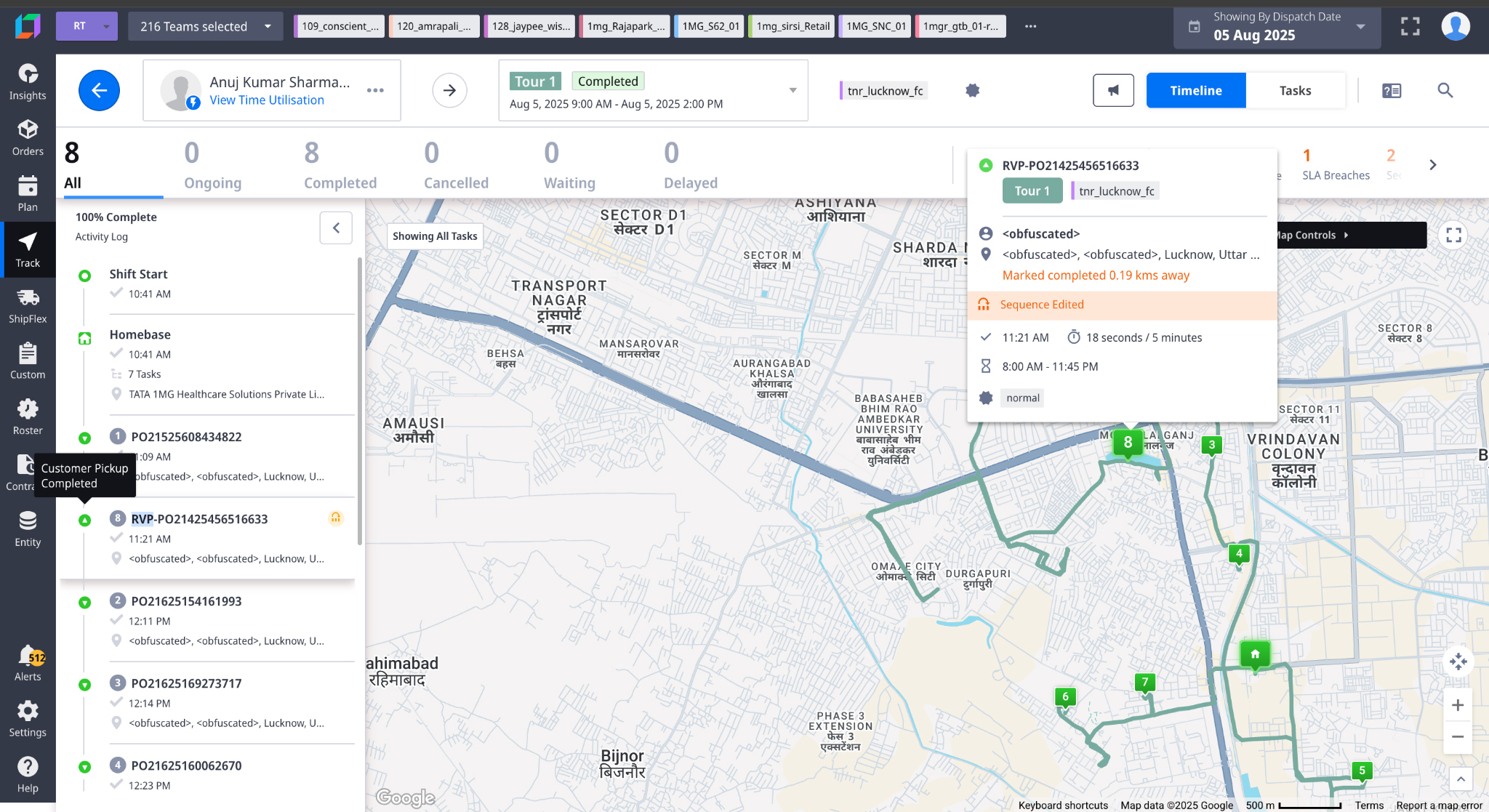

Provide ops with a live map plus auto-alerts for traffic, HOS risks, or dwell overruns, enabling proactive reroutes and real-time customer notifications.

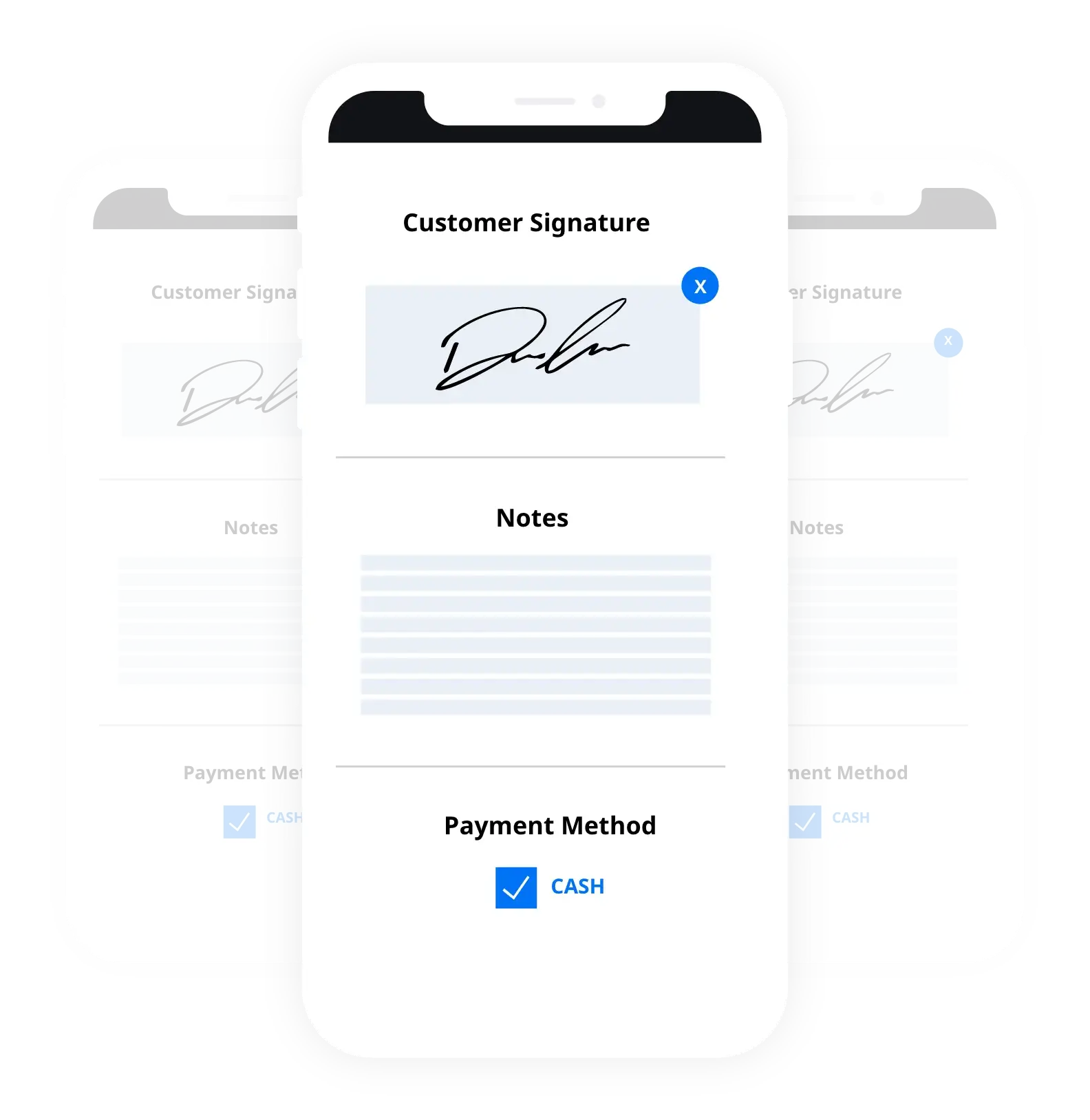

Equip drivers with optimized navigation, load-secure checklists, photo proof-of-delivery, and e-signatures, feeding instant status and compliance data back to HQ.

Surface reverse-haul opportunities for pallet returns, surplus materials, or supplier pickups, converting deadhead miles into cost savings and sustainability gains.

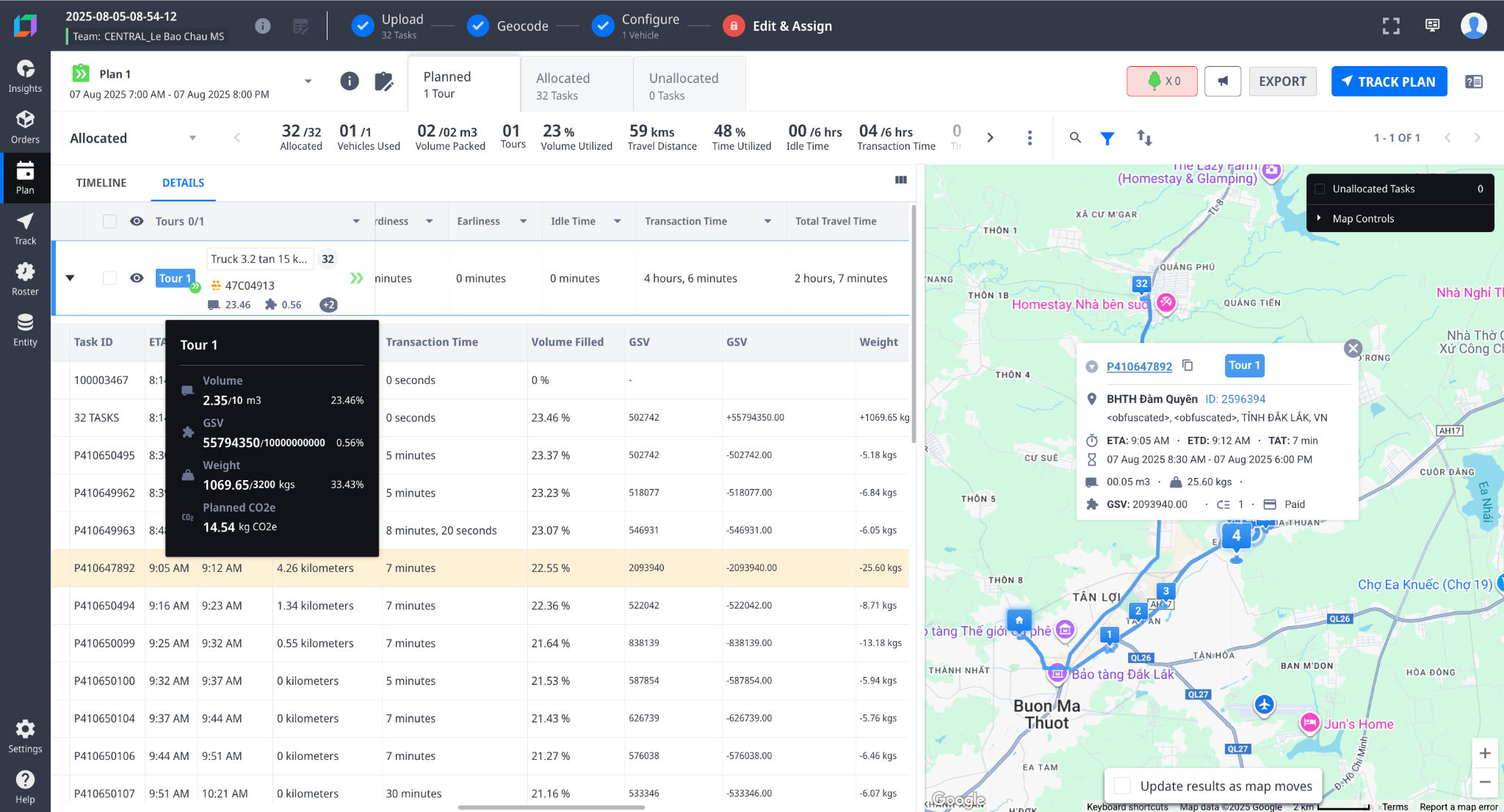

Route Optimization

Build cube/weight-balanced, multi-stop routes for lumber, drywall, and seasonal goods heading to stores and job sites, trimming empty miles while honoring lift-gate or boom-crane constraints.

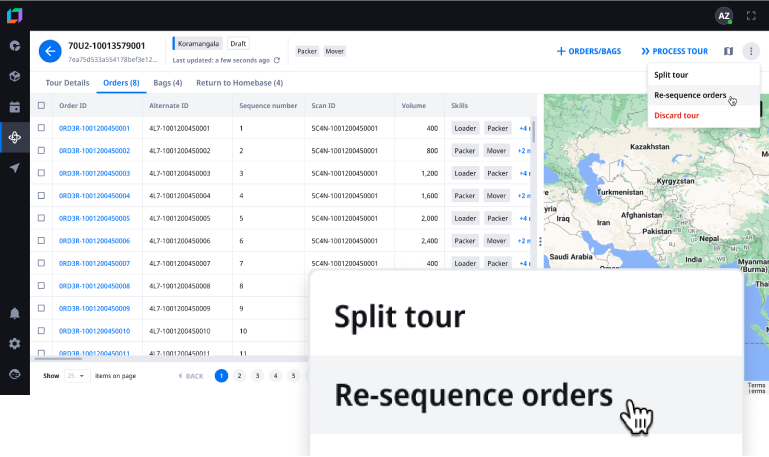

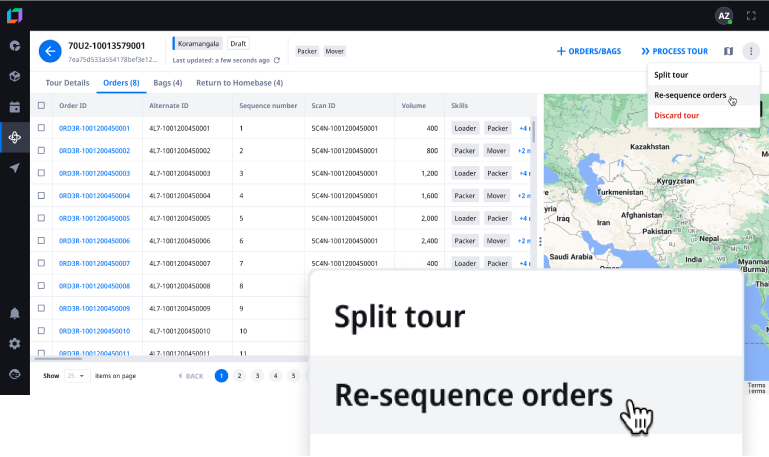

Dynamic Re-sequencing

Auto-elevate urgent job-site drops when crews are waiting, reshuffling lower-priority stops so critical materials still arrive on time without adding trucks.

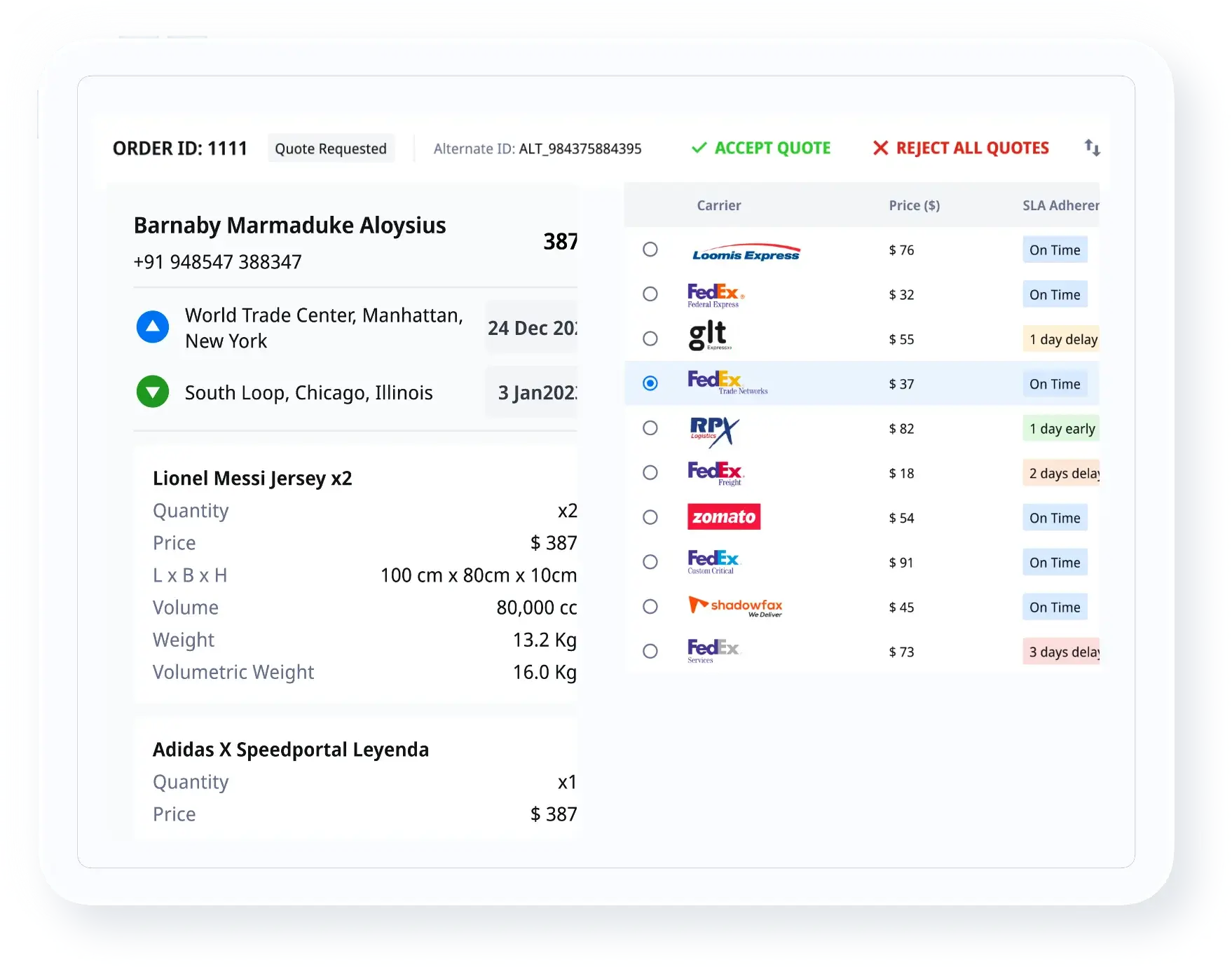

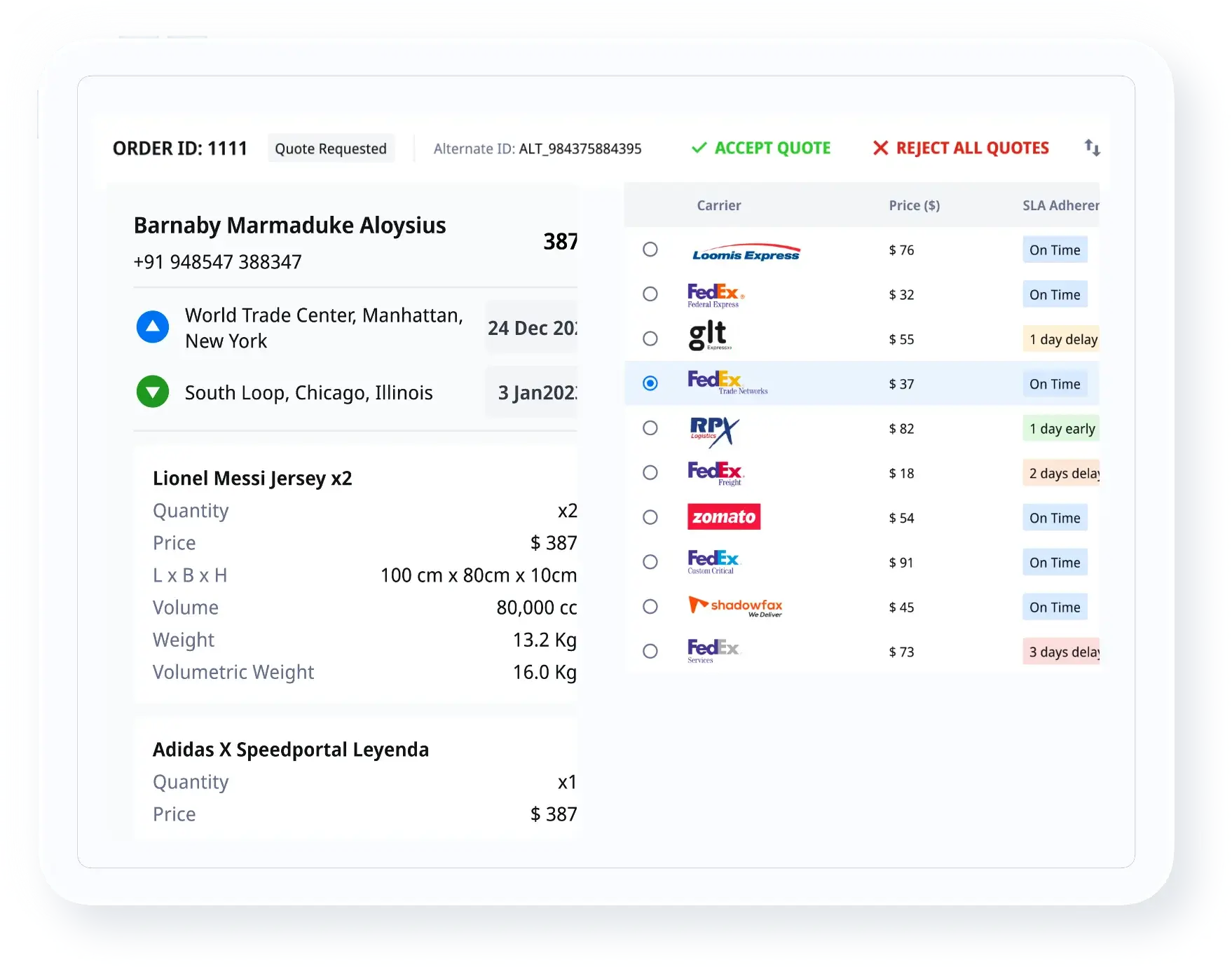

Dynamic Carrier Selection

Use ShipFlex to allocate each load to the optimal DC, cross-dock, flatbed, or LTL partner, balancing cost, capacity, and oversized-item handling needs.

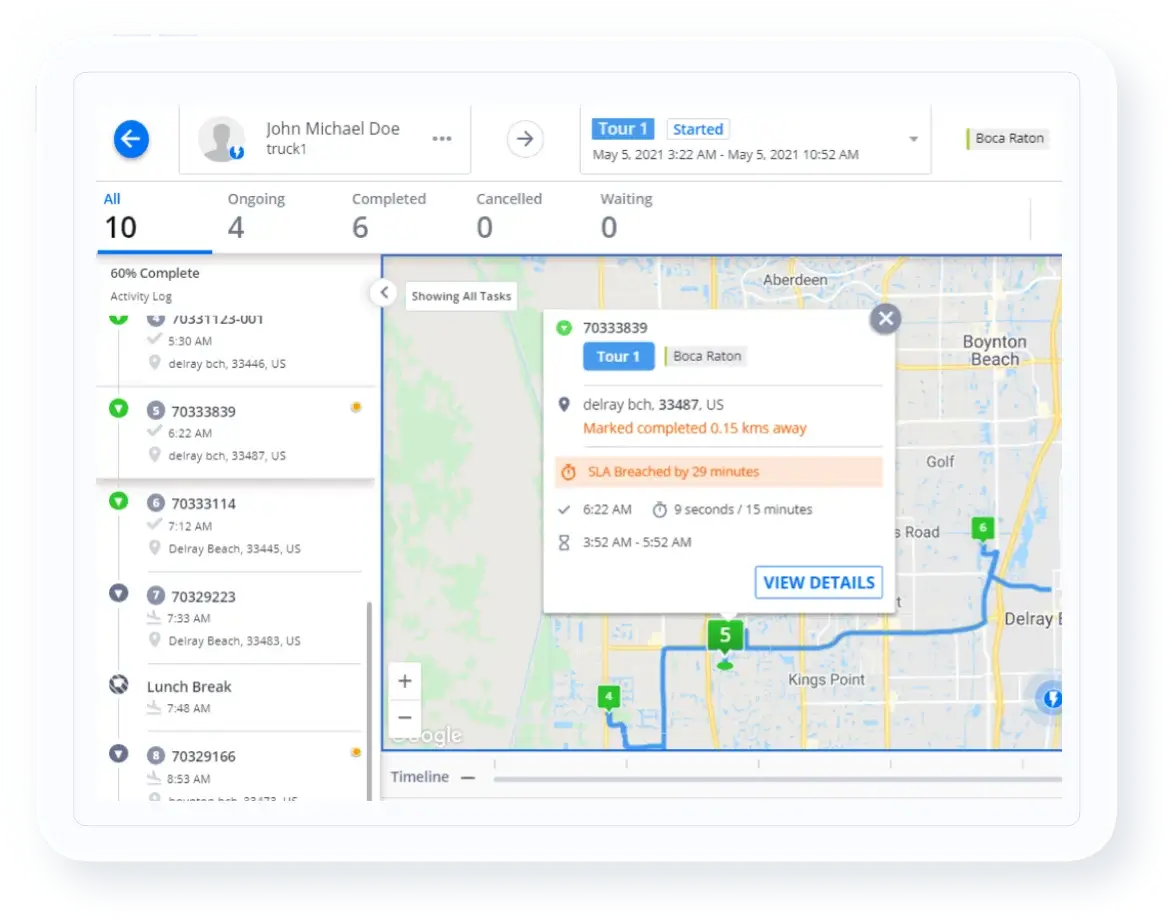

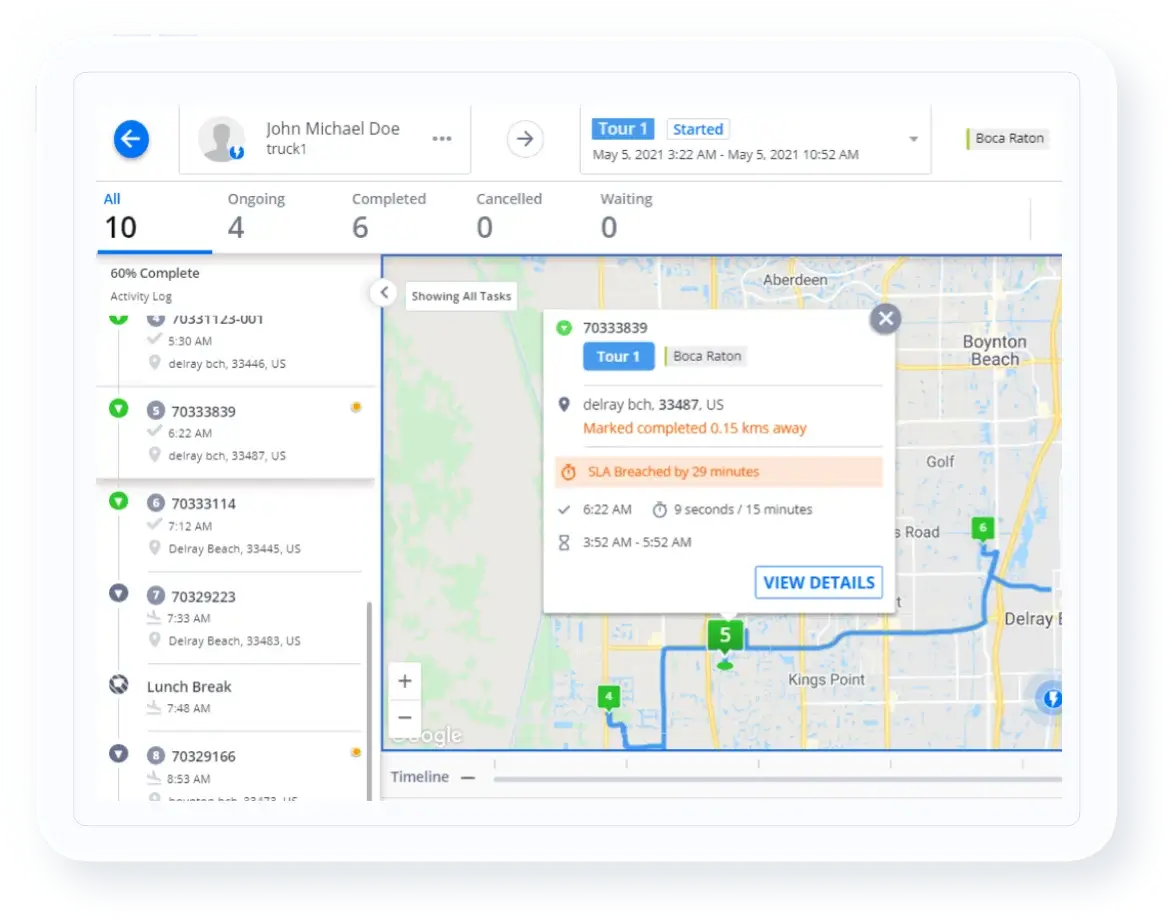

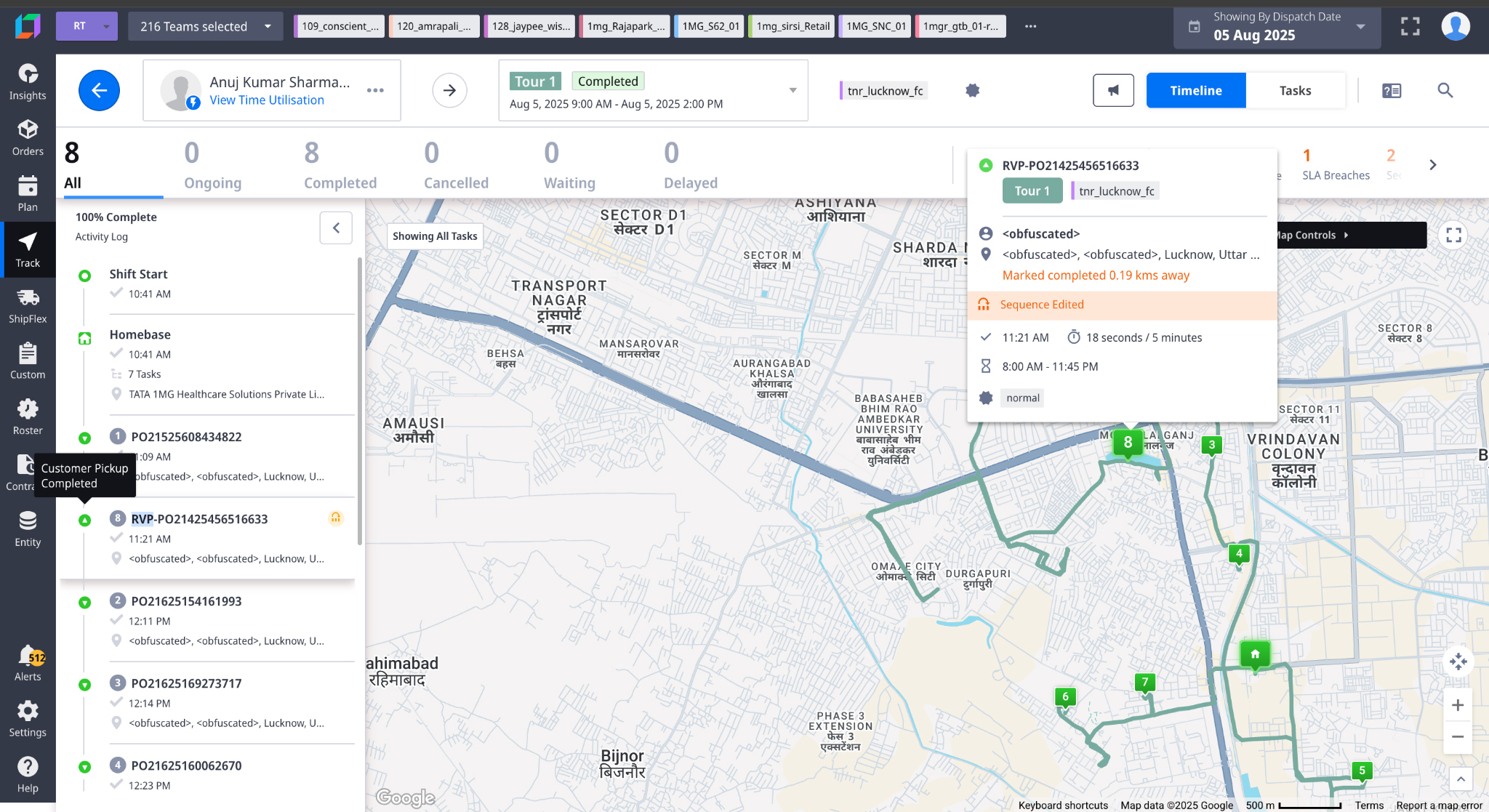

Control Tower

Provide ops with a live map plus auto-alerts for traffic, HOS risks, or dwell overruns, enabling proactive reroutes and real-time customer notifications.

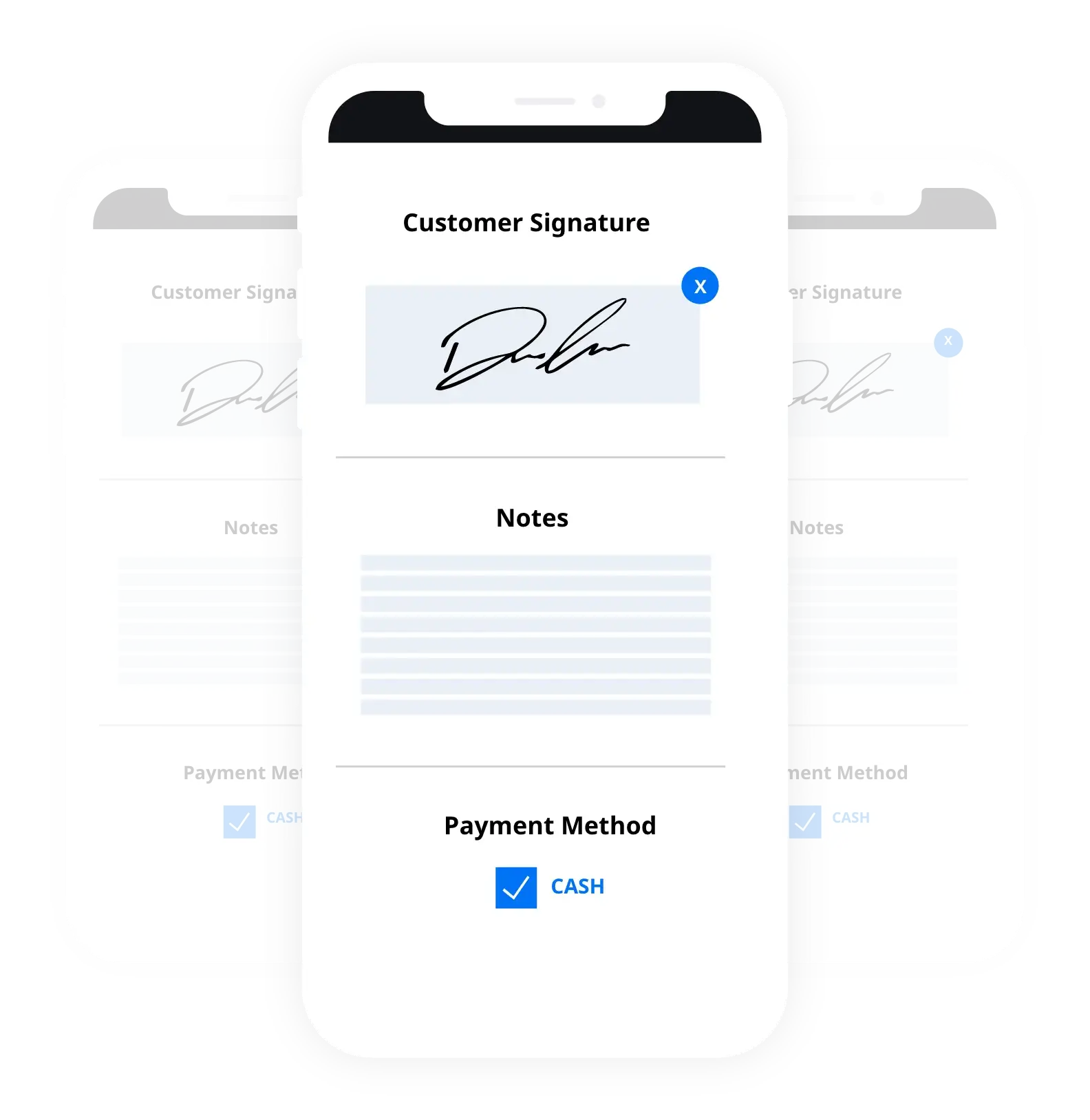

Driver App POD

Equip drivers with optimized navigation, load-secure checklists, photo proof-of-delivery, and e-signatures, feeding instant status and compliance data back to HQ.

Returns Planning

Surface reverse-haul opportunities for pallet returns, surplus materials, or supplier pickups, converting deadhead miles into cost savings and sustainability gains.

Success Stories

Croma’s End-to-End Logistics Overhaul

Dynamic routing, control-tower visibility, and a driver app unified operations for faster, fully digitized deliveries.

Driver utilization rate

Digitalization of manual efforts

Express delivery achieved

Visibility of daily dispatches

Latest Locus Insights

Storefronts at the Heart of the Omnichannel Revolution

Smart Change as a Catalyst for All-Mile Retail Innovation