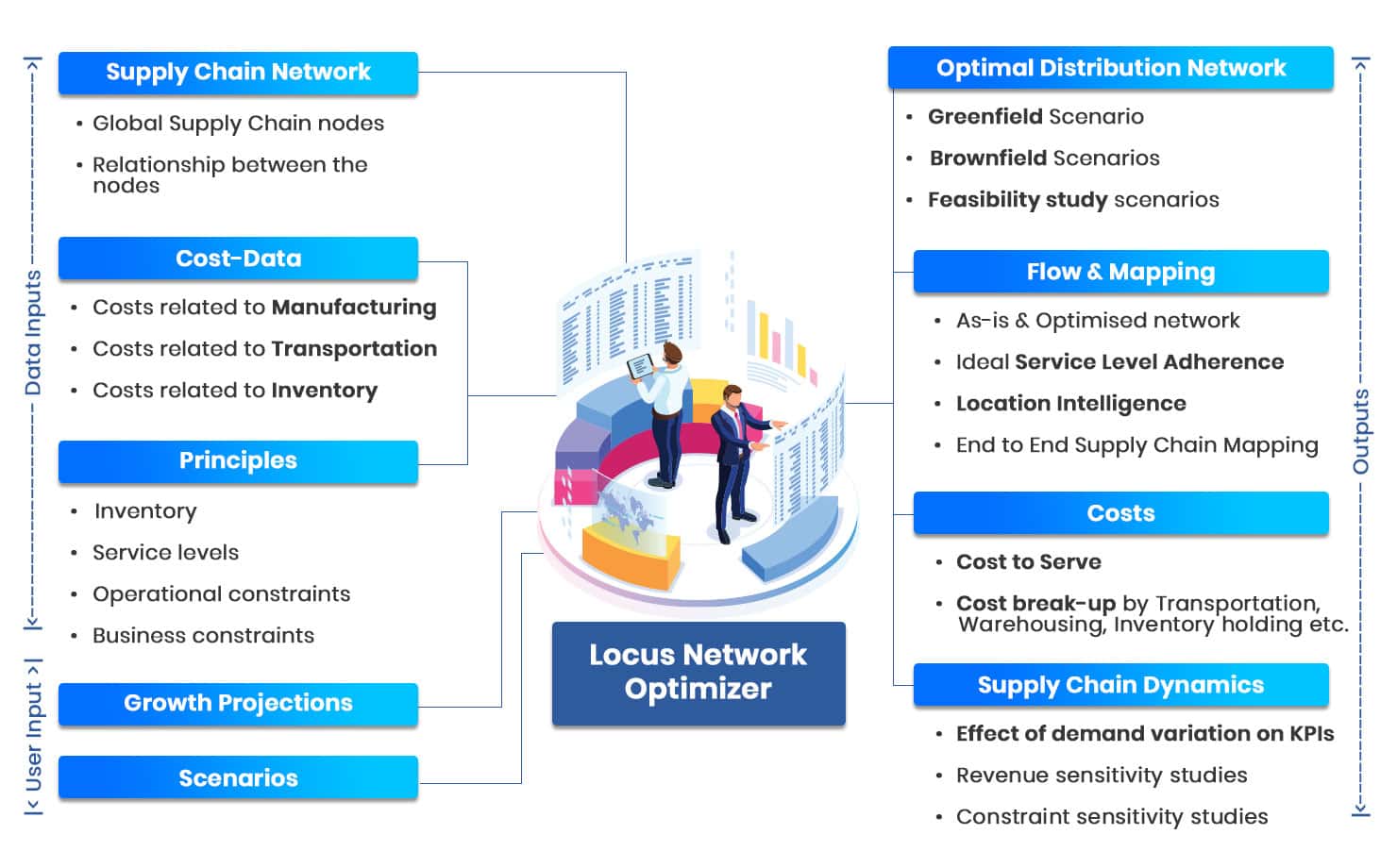

End-to-end supply-chain simulation & optimization basis minimizing total landed cost. Locus will model the supply-chain bottom-up and iteratively optimize for various scenarios and output the cost impact & re-designed supply-chain

Flow

Optimization

Flow-based remapping to optimize Total Landed Cost (Logistics + Warehousing) while maintaining existing/ improving service levels.

Location

Optimization

Identifying optimal locations for Warehouses/RDCs for both consolidation and new warehouse opening scenarios

Inventory

Optimization

Multi-Echelon inventory optimization at every layer of supply-chain and identifying optimal safety+cycle stock levels so as to lower inventory holding costs.

HOW IT WORKS

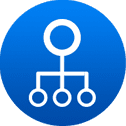

In the global model, with Vendors and Warehouses distributed across the globe, sourcing becomes a dynamic process and strategic sourcing can result in substantial cost-saving opportunities. As a part of this exercise, Locus will optimize end-to-end supply-chain and run simulations to minimize total landed cost.

Sourcing

Rules

Generate Sourcing Rules to optimize Total Landed Cost (Logistics + Warehousing) while maintaining existing/improving service levels.

Transportation

Optimization

Identifying the most cost-efficient mode of transportation while maintaining current Service Levels (or improving upon them) and modeling all associated costs

Inventory

Optimization

Multi-Echelon inventory optimization at every layer of supply-chain and identifying optimal safety+cycle stock levels so as to lower inventory holding costs.

HOW IT WORKS

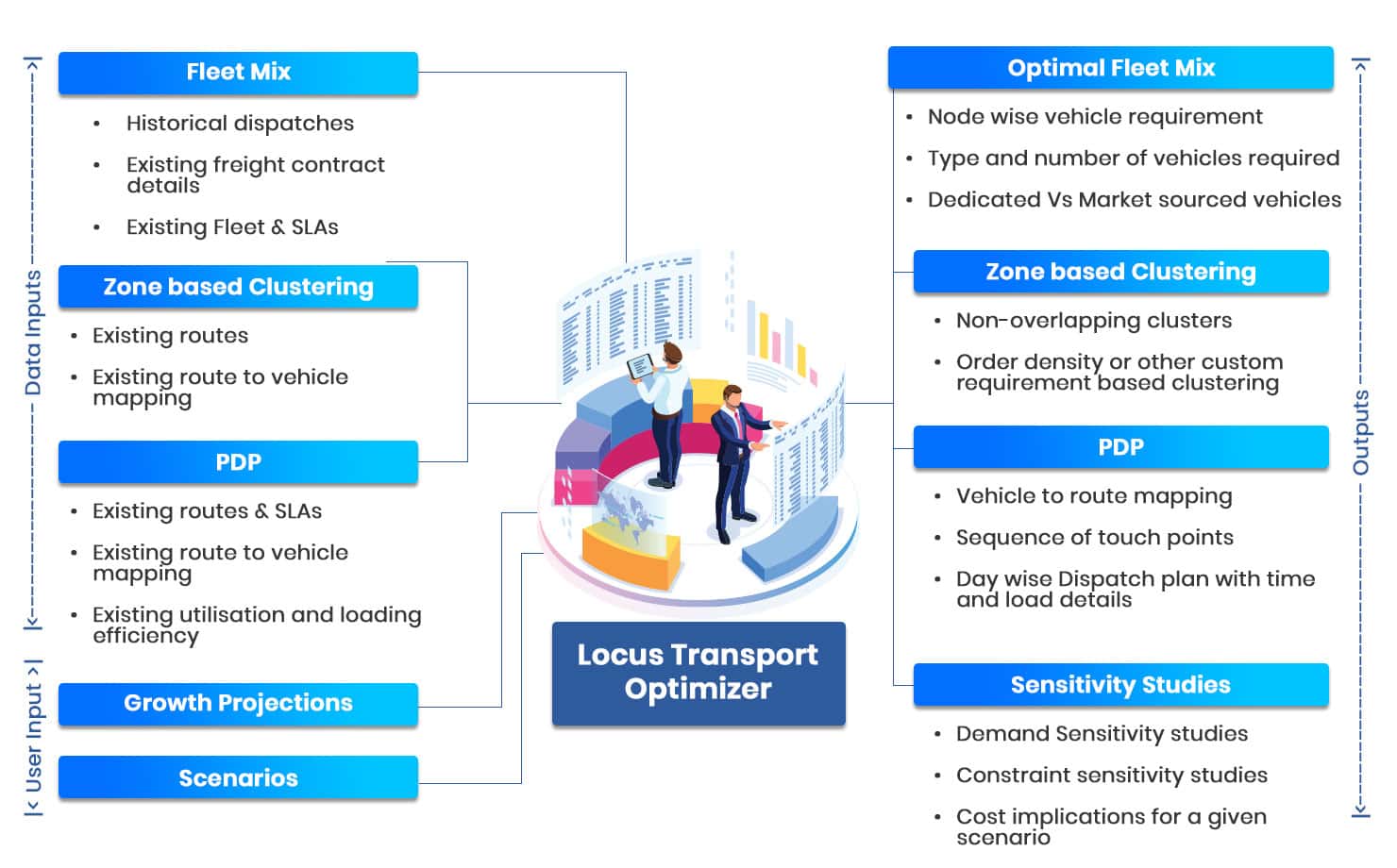

Optimise delivery/fulfillment route plans, for low vehicle travel time and distance traveled, high vehicle utilization and minimized overall logistics cost while respecting constraints.

Fleet Mix

Planning

Planning ideal fleet-mix at each Warehouse/DC/RDC to ensure maximum fleet utilization and minimum fleet costs while ensuring committed service-levels.

Zone-Based

Clustering

A given geographic region can be divided into multiple zones, followed by generation of Non-overlapping clusters for minimised logistics cost and better mapping, while respecting constraints

Permanent

Dispatch Plan

Generate delivery/fulfillment route plans, for minimising vehicle travel time and distance travelled, maximising vehicle utilisation and reducing overall logistics cost, while respecting constraints.

HOW IT WORKS

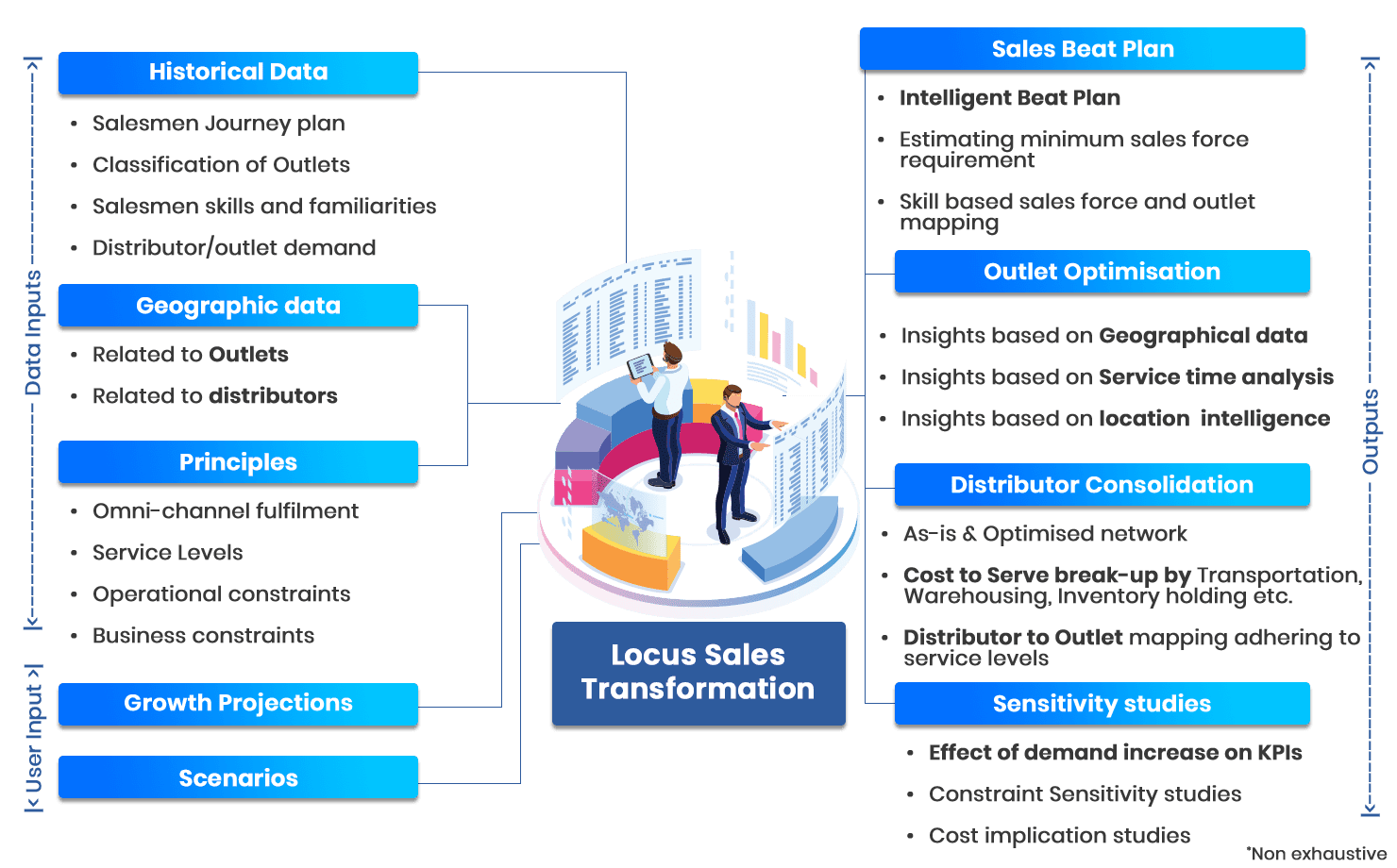

Omni-channel fulfillment is becoming the top priority for organizations and owing to complexities in terms of product mix and market dynamics, sales transformation is essential for market differentiation and value growth.

Outlet Level

Optimization

Locus provides mapping of outlets, service time analysis and revenue mix based on sales and product combination.

Permanent

Journey Plan

Generate sales beat plan based on non-overlapping clusters for most efficient sales field optimization.

Distributor to

Outlet Mapping

Basis existing demand-patterns, total landed cost, and other business and operational constraints, Locus will optimize for ideal distributor to outlet mapping.

HOW IT WORKS